Professional Additive Manufacturing Serviceslocated in Doncaster, UK

Do you require metal additive manufacturing services? If so get in touch with the

experts at Laser Additive Solutions Ltd today.

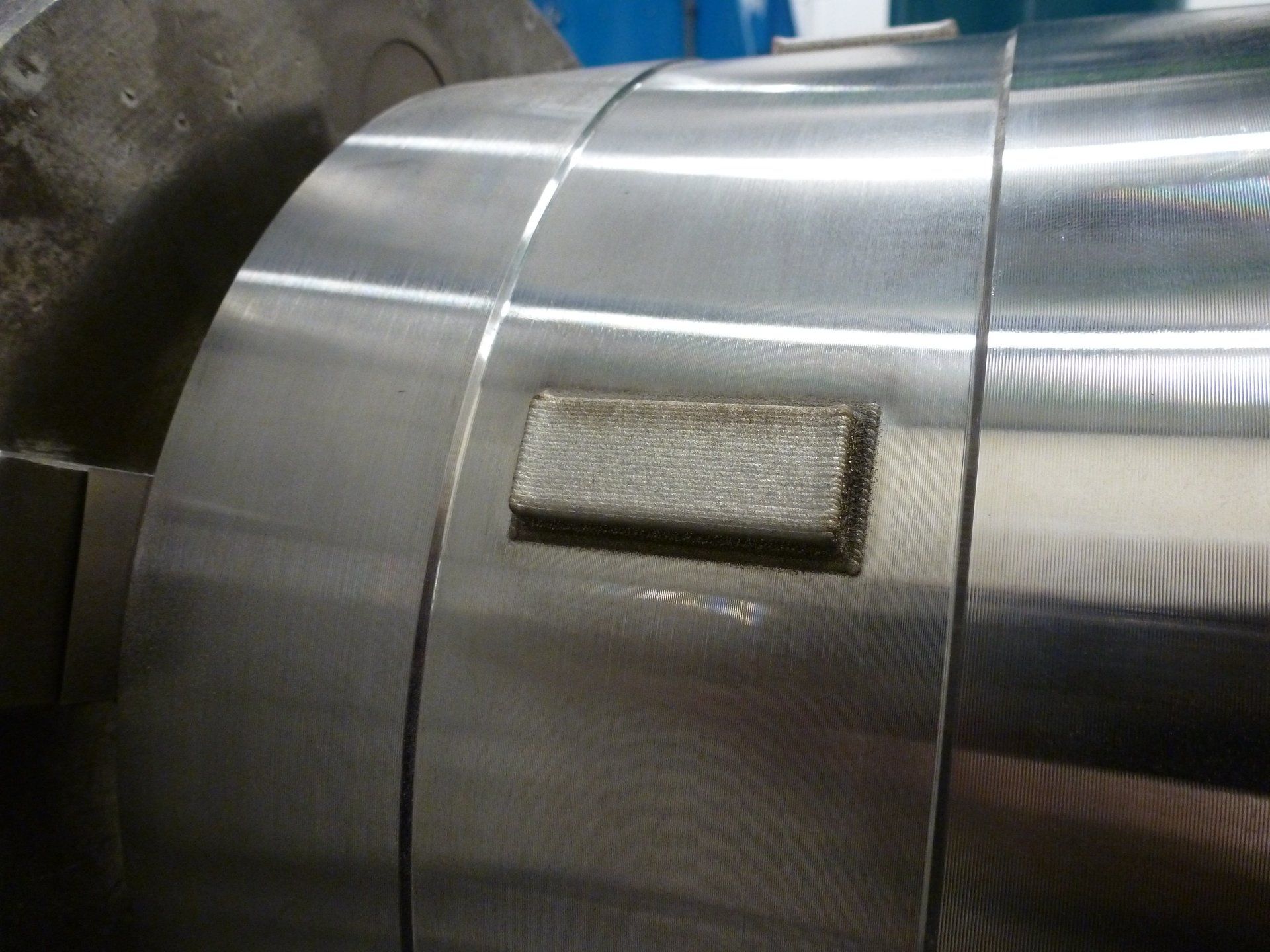

Additive Manufacturing: Building Engineering Components from Metal Powder

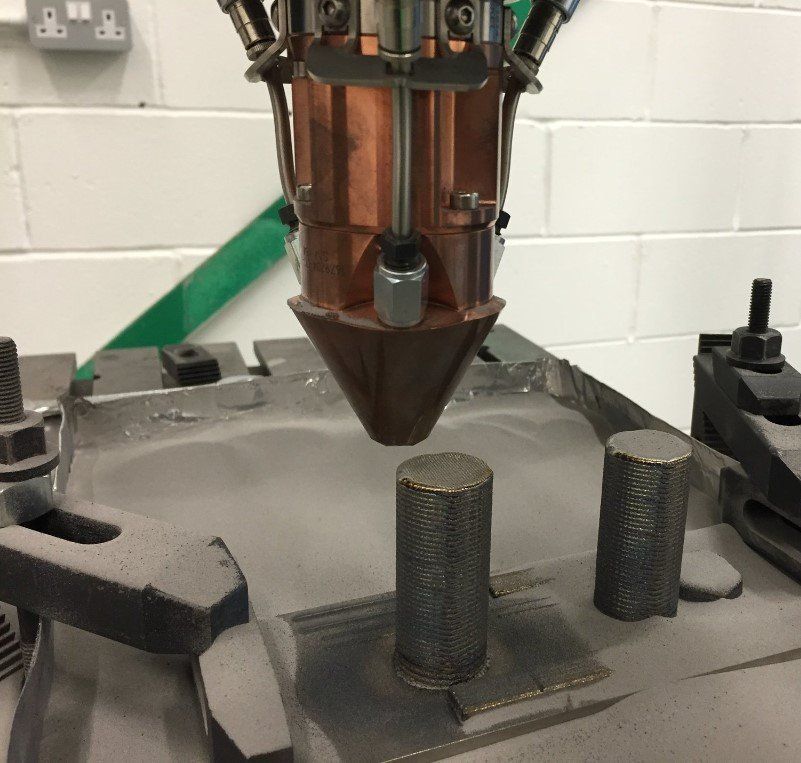

By using hundreds or maybe thousands of layers of welded material, large free-form structures can be built. Each layer is in the region of 0.4mm thick and a CAD/CAM system is used to create the desired toolpaths.

Complexity of parts can be greater than what is shown in the images below, with overhangs in the region of 25 degrees possible, but it is a 'additive' process and so the upper layers need to be able to 'sit' on layers below.

Additive Manufacturing: Materials

Here at LAS we have experience of working with the following metal based powders:

- Titanium 6-4

- Inconel Alloys (IN718 and IN625)

- Aluminium Alloys

- Engineering Steels (EN24, EN25, 4140, and 4340)

- Stainless Steels (316, Super Duplex, 420, and 17-4PH)

- Stellites (6, and 21)

- Hard-Phase Composites (WC/Ni, and NCr-CrC)

- Tool and HSS Alloys (D2, M2, H13, Vanadis)

LAS also has significant experience of working with the following base materials:

- Cast Iron

- Mild Steel

Additive Manufacturing: Quality and Testing

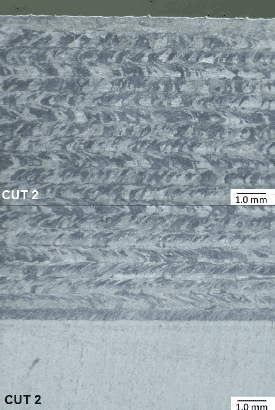

LAS work according to the quality standards established within our ISO 9001: 2015 accreditation. LAS have fully calibrated measuring equipment to monitor the following Key Process Variables:

- Laser Power

- Laser Beam Profile (spot size)

- Powder Feedrate and gas flows (argon or helium)

- Machine Processing Speed

- Atmospheric Oxygen Content (ppm) - when using atmospheric welding chamber

LAS work closely with Doncaster Analytical Services Ltd

who carry out independent metallurgical investigation including microscopy analysis, hardness testing, and mechanical property testing.

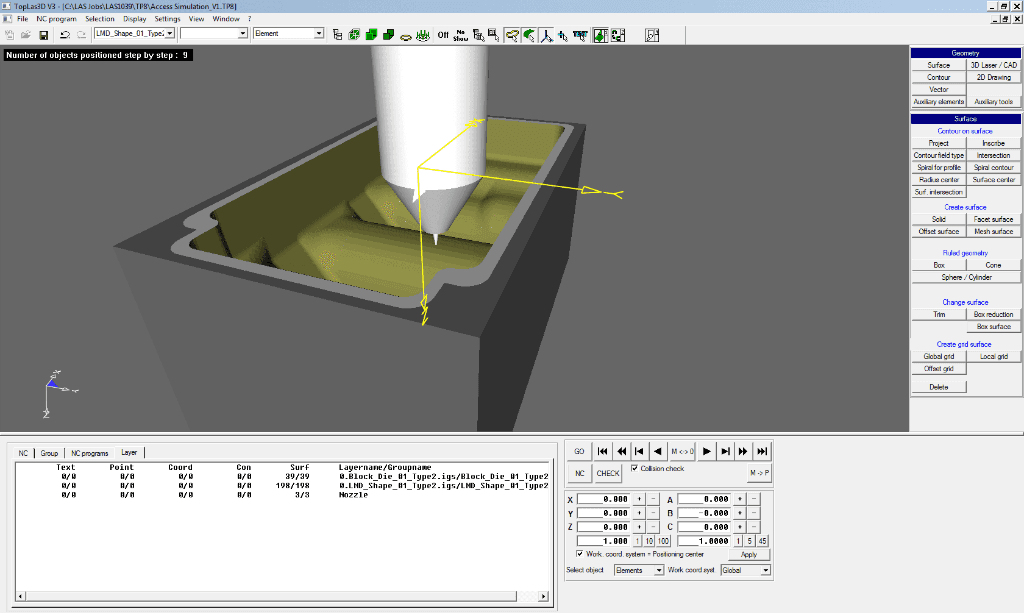

Additive Manufacturing: Toolpath Programming

LAS use 5-axis CAM programming software for all laser processing activities. Developed toolpaths are safely stored for traceability reasons. Many Additive Manufacturing projects are based on customer supplied CAD models - LAS then go about producing metallic near-net shapes representing the supplied CAD models.

Additive Hybrid Manufacture

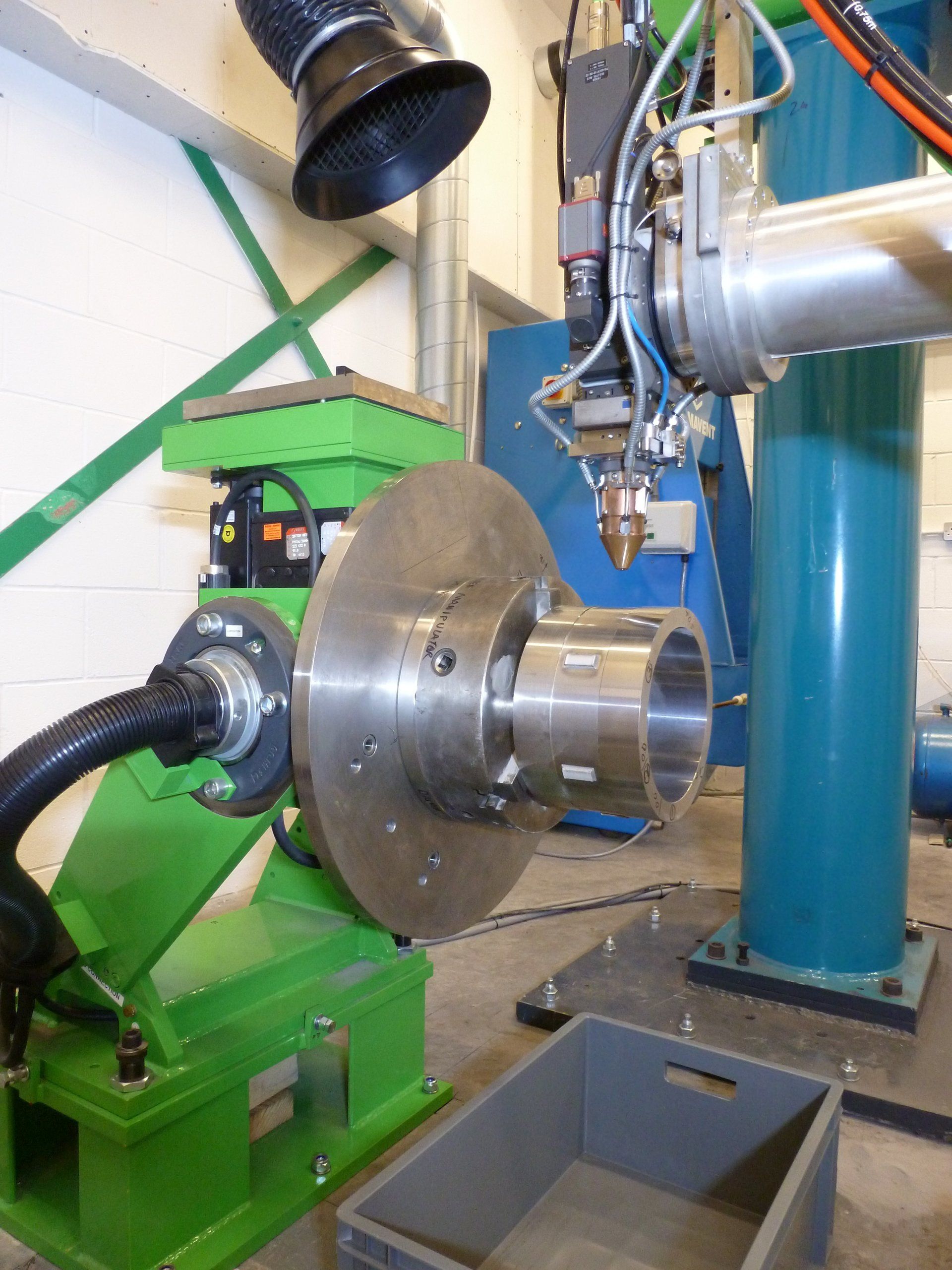

- Allows reduction of base component raw material - deposit near-net shape features rather than starting with a significantly over-sized billet

- Very precise addition of near-net shape material just where it is required

- Use higher performing LMD material compared to base component e.g. Stellite for high wear resistance applications

- Can deposit onto a variety of shapes - process is CAD/CAM driven

- All process variables are monitored and controlled - results in a highly repeatable manufacturing process

If you require metal Additive Manufacturing services, call Laser Additive Solutions Ltd on

01302 868 988