Automated Laser Welding Services in Doncaster UK

What is Laser Welding?

Laser Welding is a highly precise and efficient joining process that uses focused laser energy to create clean, strong, and accurate welds. Known for its speed, minimal heat distortion, and ability to handle complex or delicate components, laser welding has become an essential technology across industries such as automotive, aerospace, medical devices, and electronics. Whether used for micro-welding or high-volume production, this advanced method delivers consistent quality and superior performance compared to traditional welding techniques. Laser Additive Solutions Ltd has been offering Laser Welding services for over 10 years with combined experience of more than two decades.

Our Equipment

We have two laser processing cells at LAS dedicated to Automated/Production Laser Welding.

Cell 1 (See above- left):

- 2kW TRUMPF Disk Laser

- 5 Axis REIS Gantry/Manipulation

- Powder Feeder

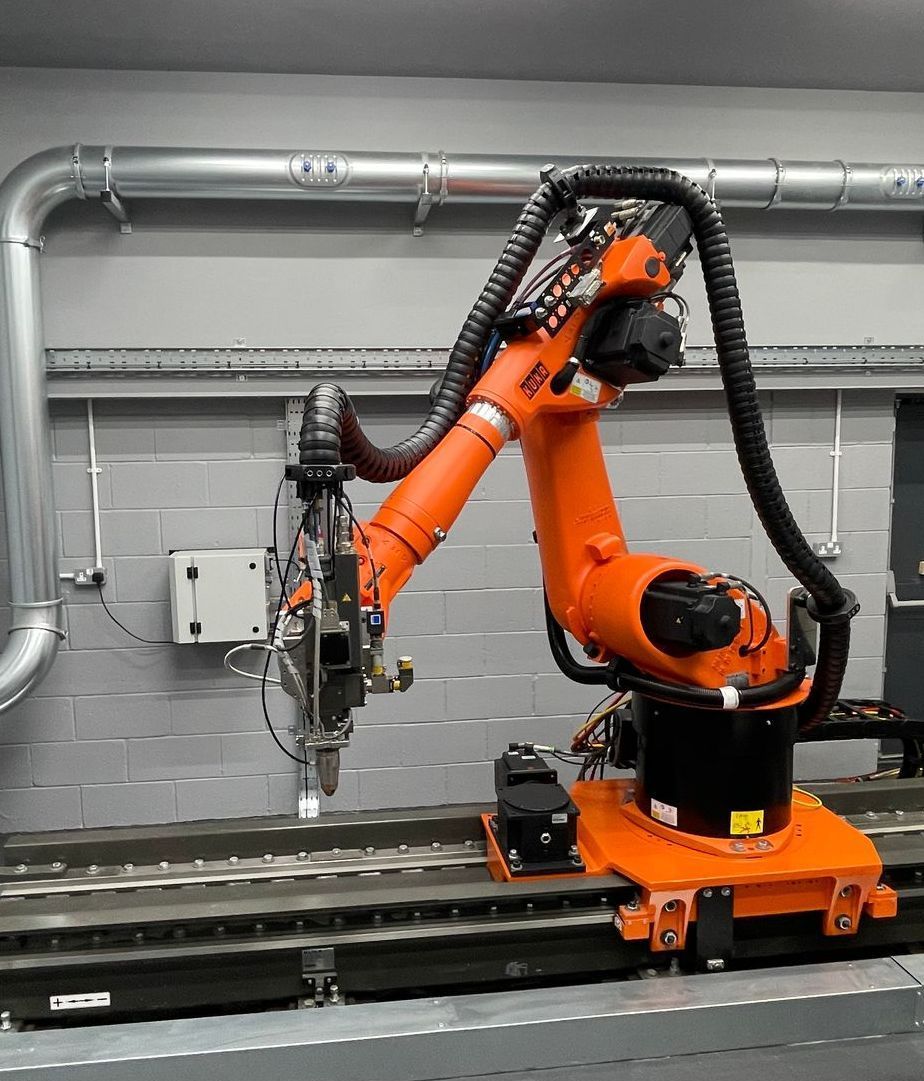

Cell 2 (See above - Right)

- 3kW TRUMPF Disk Laser

- 6 Axis KUKA High Accuracy Robot

- Powder Feeder (with Wire Feeder capabilities)

LAS can offer mobile laser welding or handheld laser welding services too.

What are the benefits of Laser Welding?

01

Precision & Accuracy

02

Low Cost

03

Speed & Efficiency

04

Minimal Heat Distortion

TECHNICAL DATA

APPLICATIONS OF LASER WELDING

Aerospace component Welding

Laser Welding is commonly used in a variety of applications in aerospace. For example where a sensitive electronics housing requires joining, laser welding is ideal due to the minimal heat input keeping the assembly below 100°C.

Surgical Instruments

Laser Welding is ideal for surgical instruments. The low heat input from LW has reduced distortion compared to other processes, which makes it brilliant for these delicate applications.

Nuclear Reactor Components

Similarly to the reason for welding surgical instruments, certain nuclear reactor components are delicate and require dissimilar metal components to be joined therefore are well suited to laser welding.