LAS Case Studies

3D printing, also known as additive manufacturing, has significantly transformed various industries by allowing complex designs to be created with precision and efficiency. Among the various materials used in 3D printing, cobalt chrome (CoCr) stands out due to its exceptional properties and diverse applications.

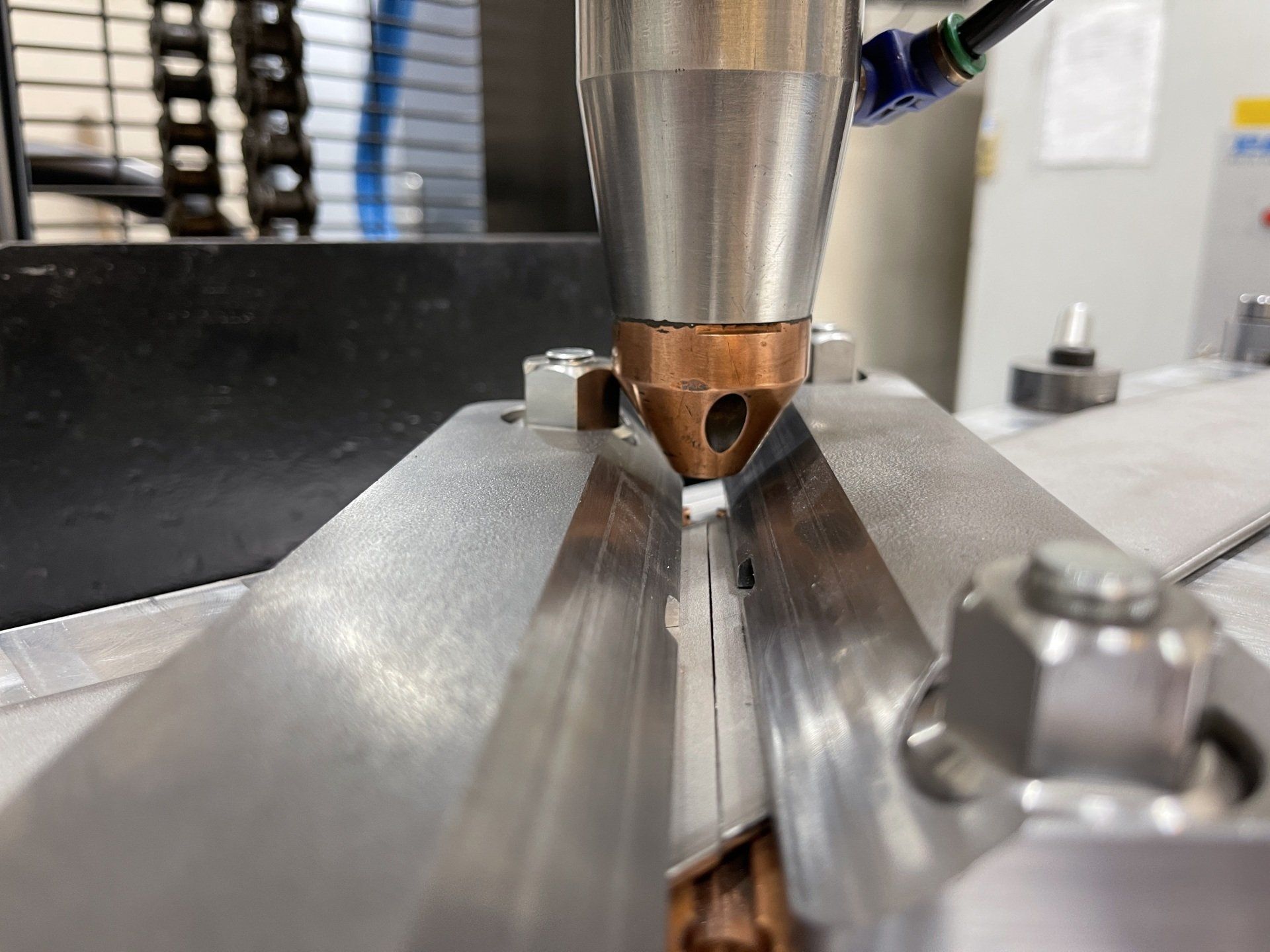

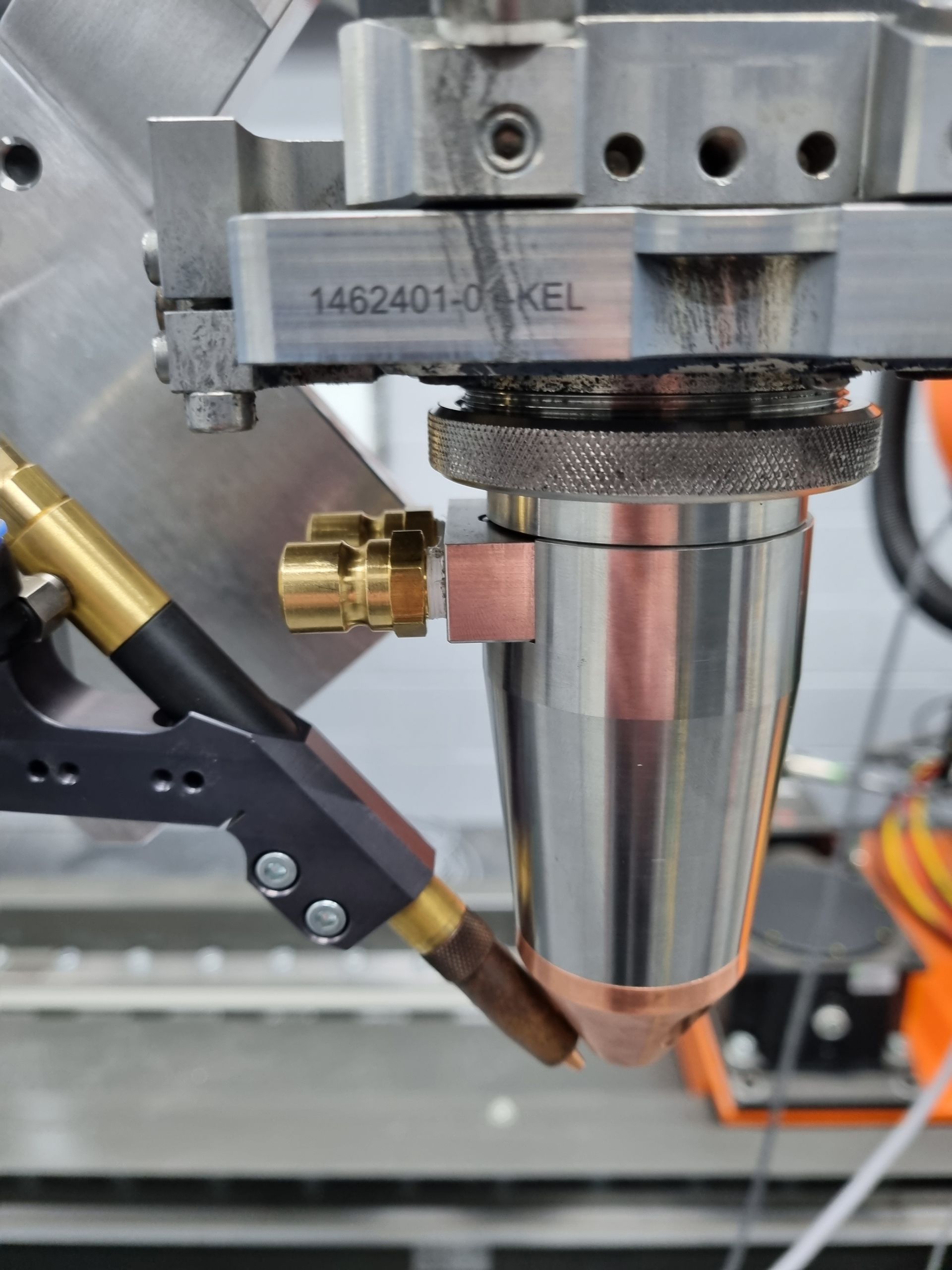

Wire Direct Energy Deposition (W-DED) is an advanced additive manufacturing process where a metal wire is precisely melted using a focused energy source, such as a laser or electron beam. This technique enables the layer-by-layer fabrication of intricate metal components, offering increased control over material deposition and making it particularly useful for applications requiring high precision and material efficiency.

Laser Additive Solutions has, recently, completed a Research and Development project funded by Innovate UK to develop the Wire DED process for Inconel 718. Inconel 718 has many applications in the Aerospace, Oil and Gas and Automotive Industry.

CONTACT US

Have a question? Send us a message and we’ll be in touch.