Advancing Turbine Manufacturing with Laser Directed Energy Deposition

In the high-performance world of aerospace turbine manufacturing, agility and precision are mission-critical. Traditional fabrication methods—casting, forging, and subtractive machining—struggle to keep up with demands for faster development cycles, complex geometries, and cost-efficiency.

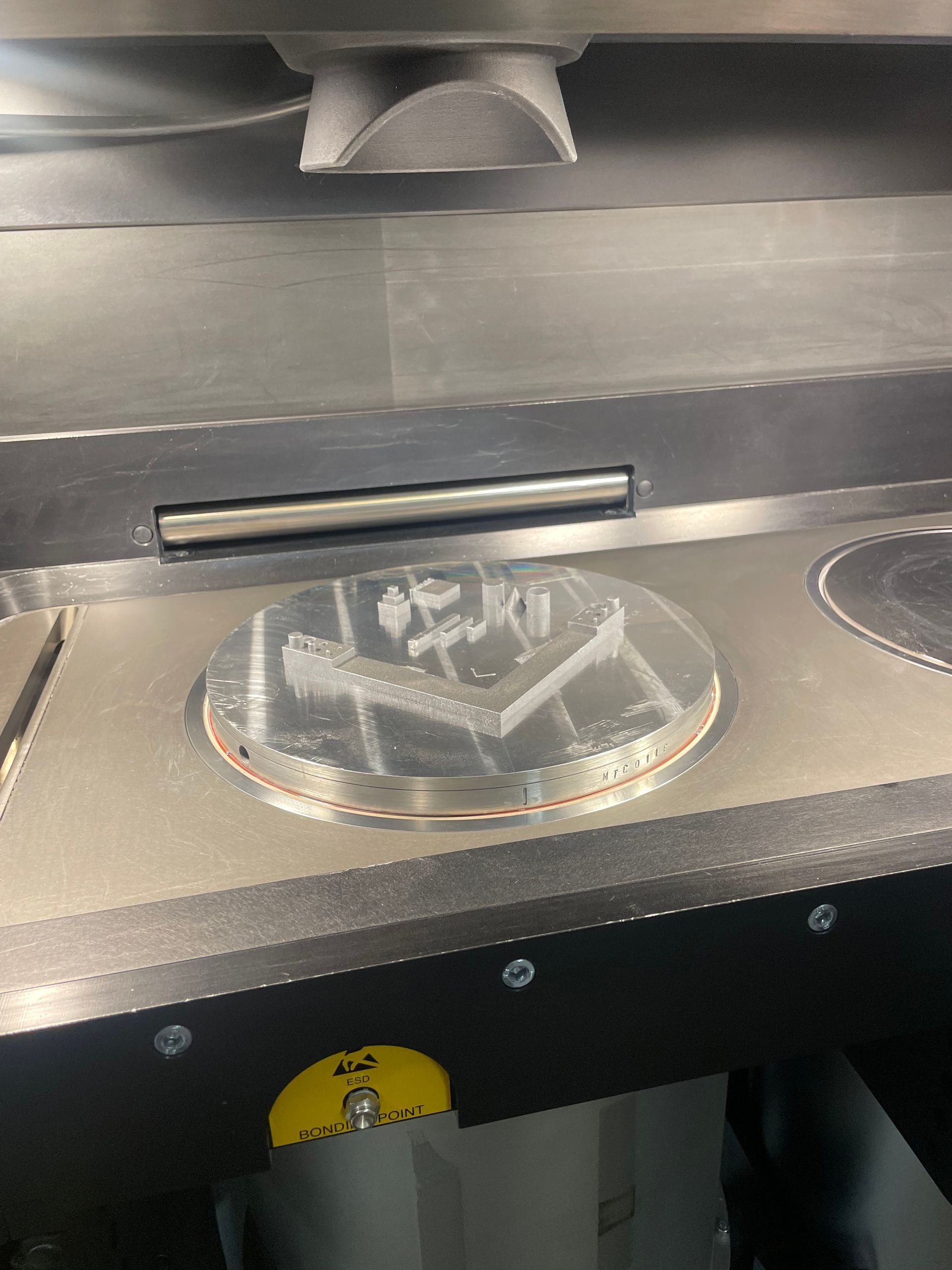

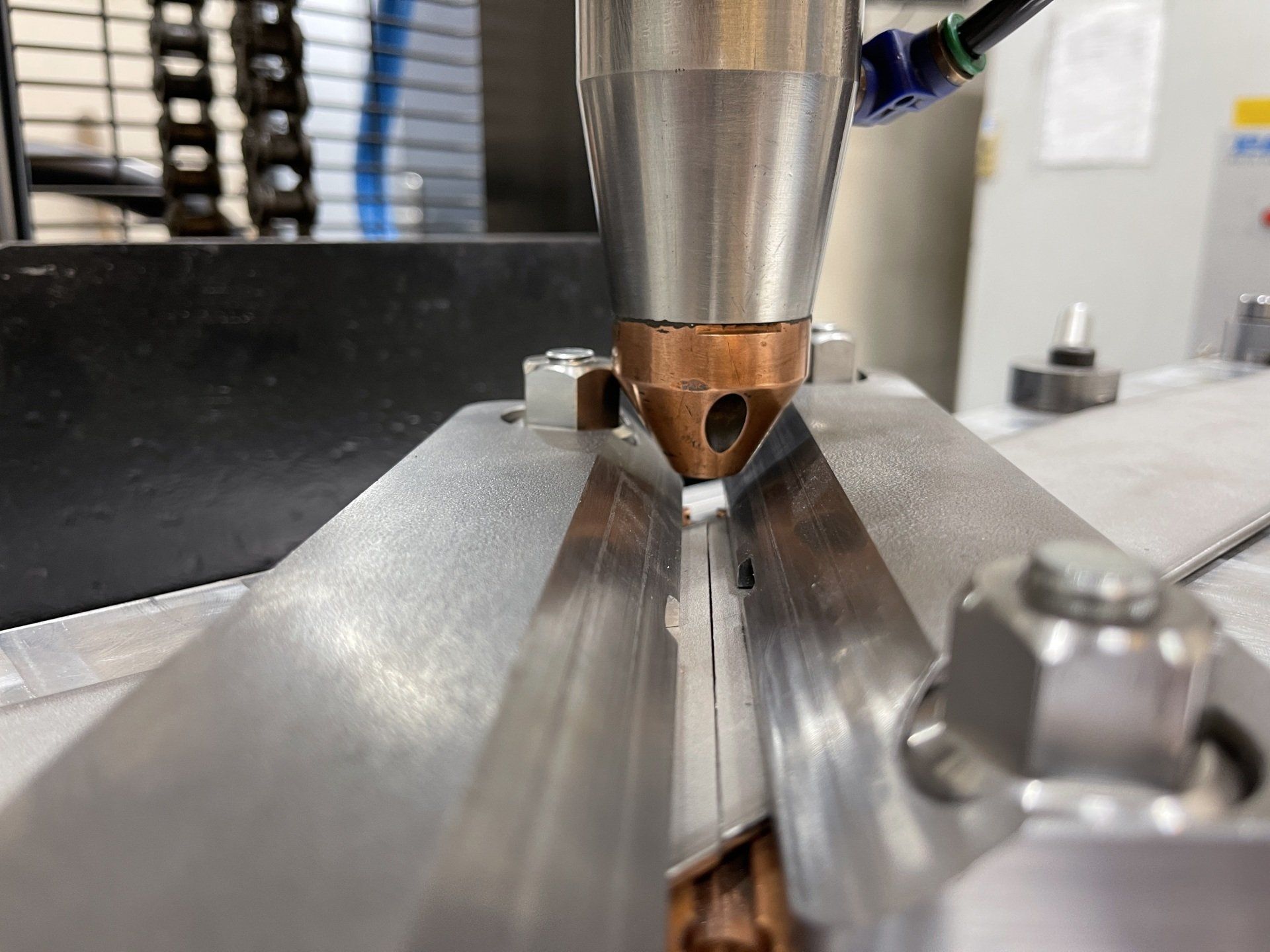

Enter Laser Directed Energy Deposition (L-DED): a form of metal additive manufacturing that offers unprecedented design flexibility, reduced lead times, and near-net shape efficiency. We are demonstrating this capability through a novel process for manufacturing Inconel 718 turbine blades, optimized for jet engine applications.

What is Laser Directed Energy Deposition?

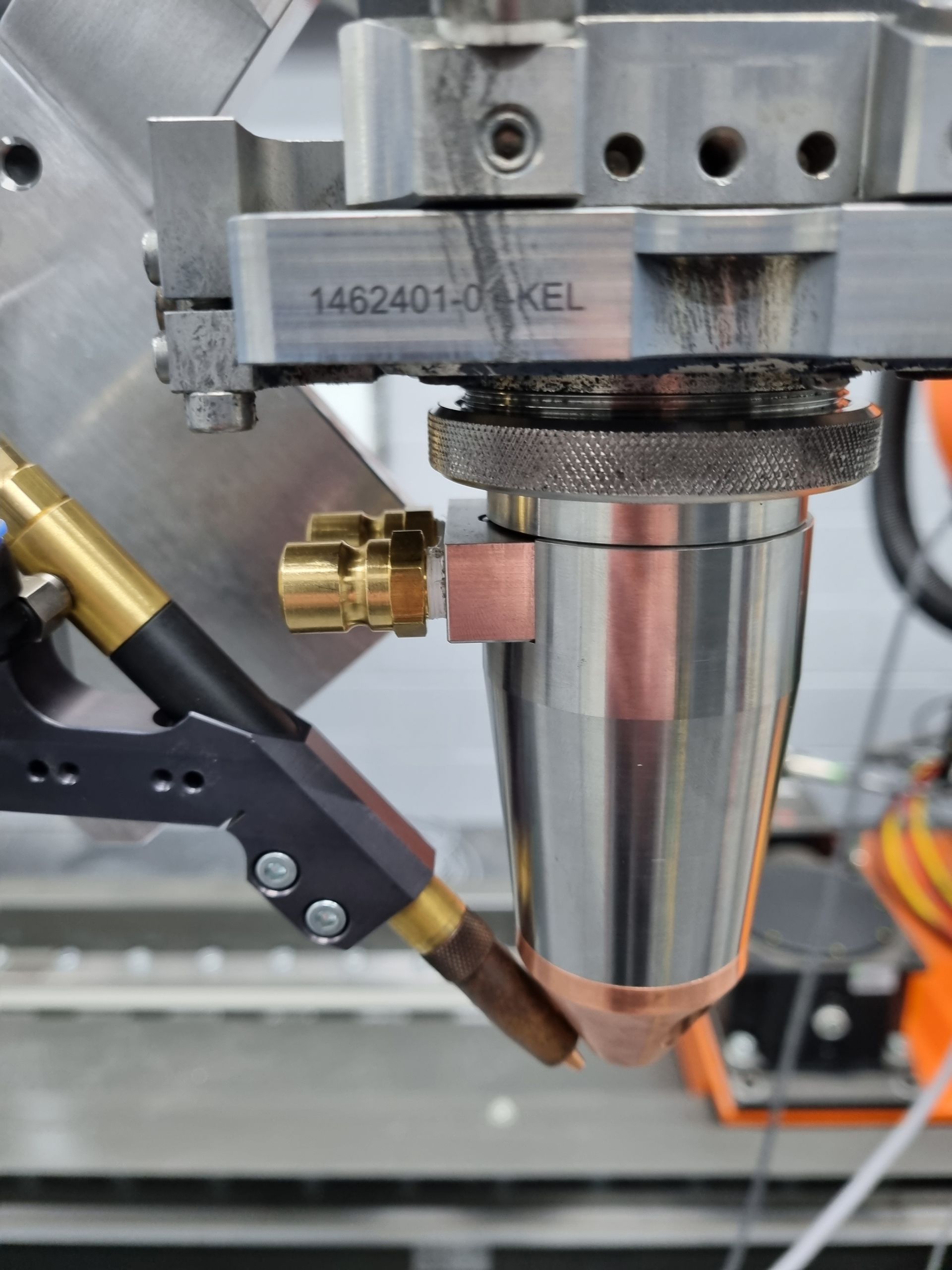

- A TruDisk 3001 laser delivering stable energy input

- A 6-axis KUKA industrial robot enabling complex multi-orientation deposition

- Full CAD-to-CAM integration for seamless digital manufacturing

- Inconel 718 feedstock for high-temperature, aerospace-grade performance

Key Benefits for Turbomachinery

For aerospace OEMs, defence contractors, and propulsion system developers, L-DED offers several transformative advantages:

- Reduced Lead Times

Eliminate long waits for forged blanks or castings—go from design to finished component in days.

- Tooling-Free Flexibility

No custom moulds, dies, or fixtures are needed—perfect for rapid prototyping, short-run production, or scalable high volume production.

- Material Efficiency

Inconel 718 is expensive. Our L-DED process minimizes waste and maximizes deposition yield with conversion efficiency reaching up to 90% with powder.

- Rapid Design Iteration

Integrated CAD/CAM workflows allow immediate implementation of design changes, ideal for R&D or performance optimization.

- Automated, Scalable Process

Robotic deposition ensures consistent, high-quality builds with minimal operator intervention—laying the groundwork for future production scaling.

Applications in Aerospace and Defence

Our current demonstration targets jet turbine blade manufacturing, with potential applications across:

- Aerospace propulsion systems

- Military turbine engines

- Industrial gas turbines

- UAV and next-gen propulsion platforms

This capability is especially relevant for UK defence programs, where agility, local supply chain resilience, and advanced manufacturing innovation are strategic imperatives.