Laser Additive Solutions Achieves Esteemed JOSCAR Accreditation

In a significant stride toward expanding its influence within the aerospace, defence, and security sectors, Laser Additive Solutions, a prominent figure driving advancements in Laser Welding and Additive Manufacturing technologies, is proud to announce its recent accreditation by JOSCAR (Joint Supply Chain Accreditation Register).

This prestigious accreditation marks a critical milestone for Laser Additive Solutions, demonstrating its commitment to maintaining the highest standards of quality and efficiency in its operations. The JOSCAR accreditation is recognized across the UK’s defence, aerospace, and security sectors as a benchmark for supplier excellence.

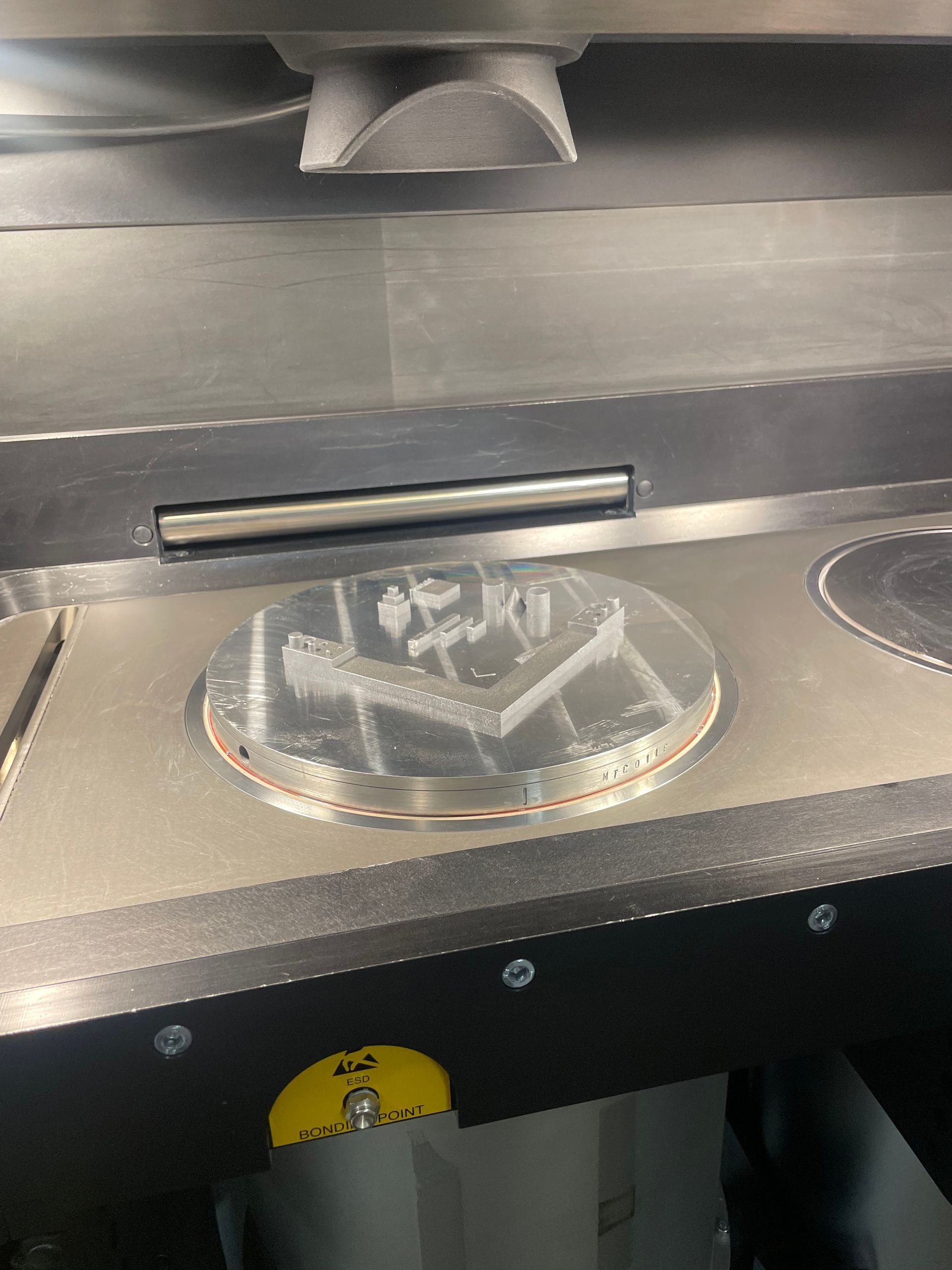

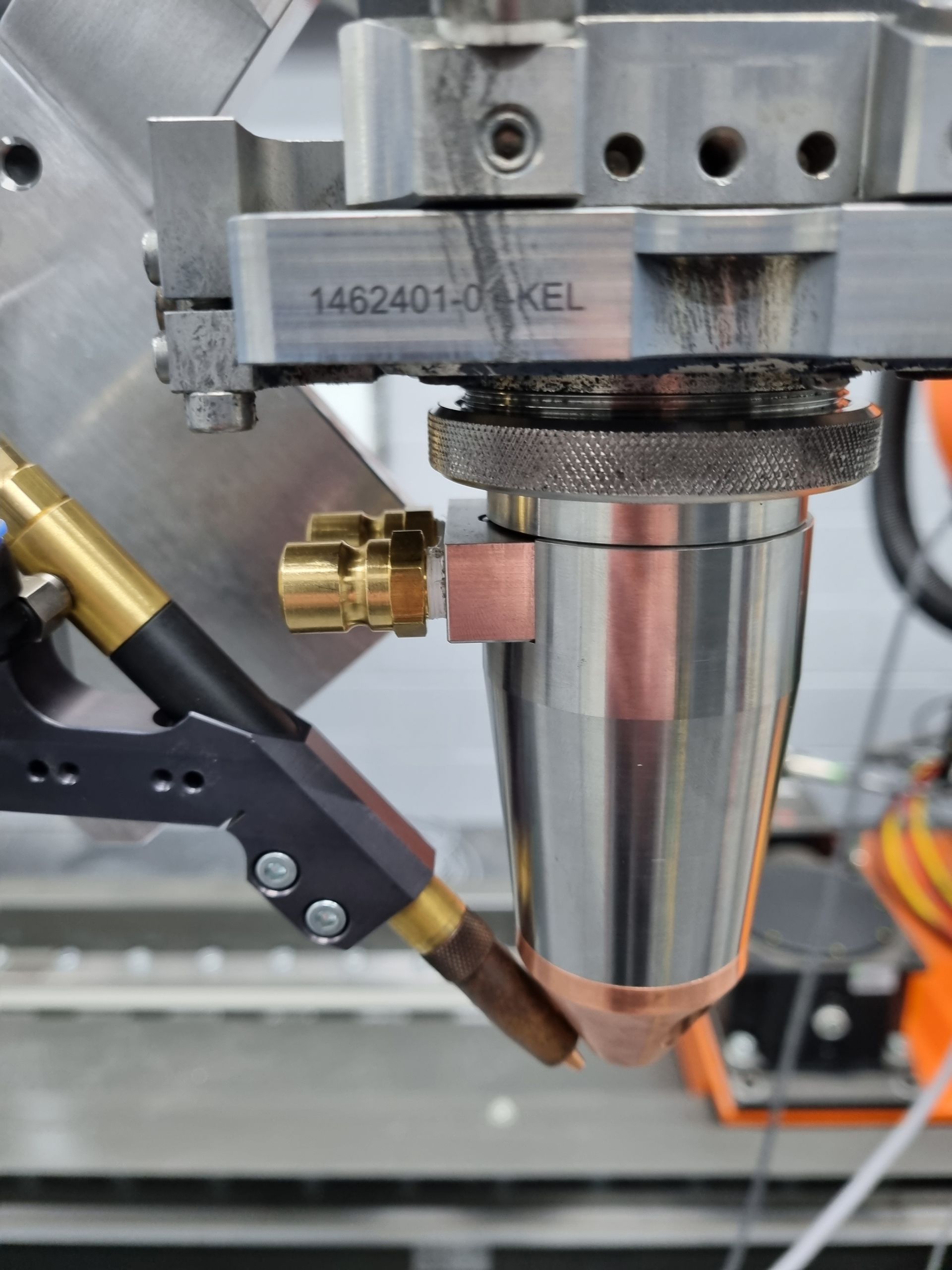

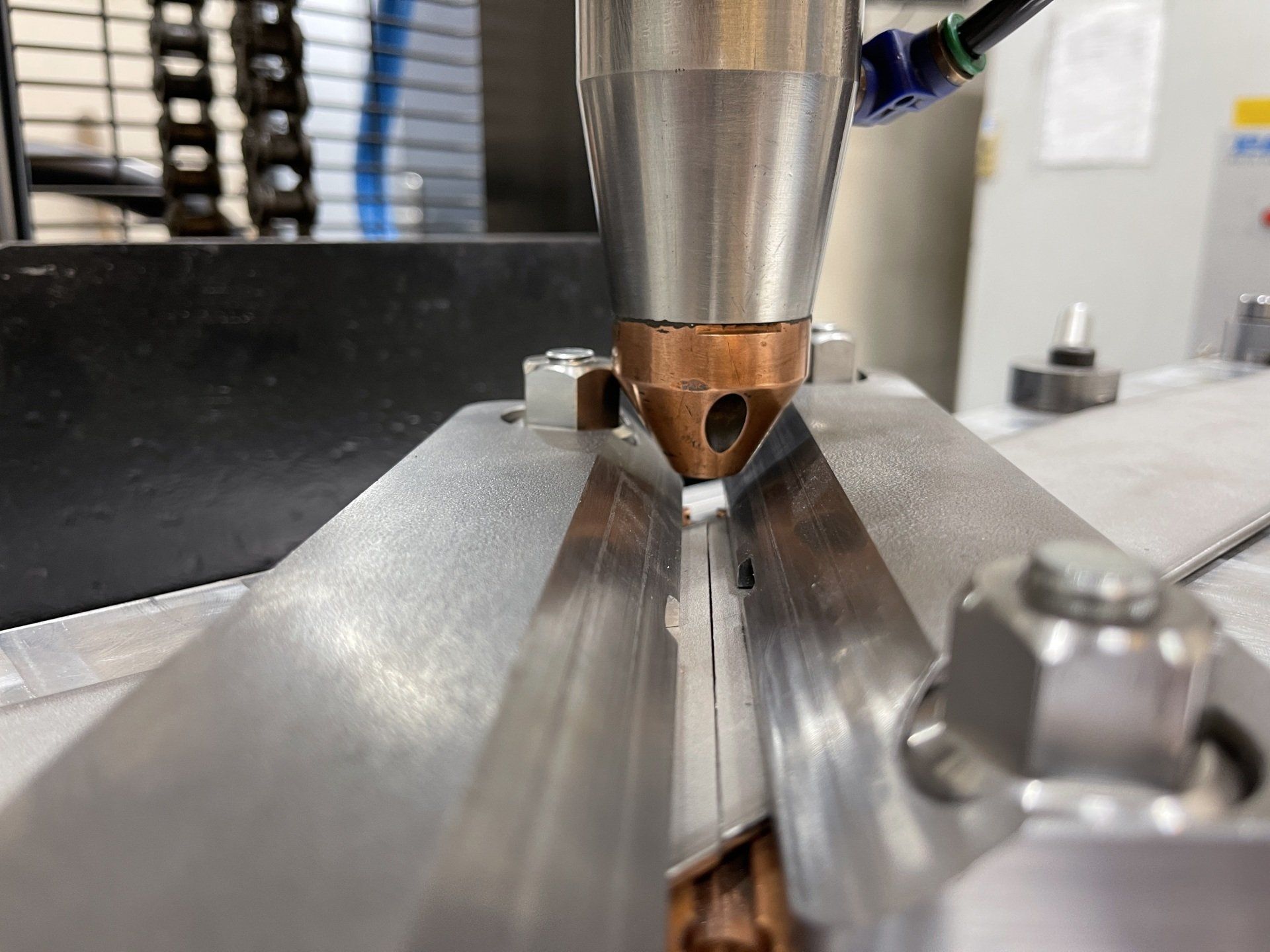

As a company at the forefront of Laser Welding and Additive Manufacturing technologies, Laser Additive Solutions has consistently showcased its capability to deliver innovative and high-quality solutions. This achievement is a testament to the company's ongoing efforts in upholding rigorous industry standards, ensuring compliance, and demonstrating its technical proficiency.

“This accreditation is a clear indication of our expertise and reliability in the field,” said Peter Brown, the Managing Director of Laser Additive Solutions. “Our advanced Laser Welding and Additive Manufacturing capabilities, coupled with our commitment to quality and innovation, make us an ideal partner for projects within the aerospace, defence, and security sectors.”

For more information about this post, contact us on enquiries@laseradditivesolutions.co.uk