Thin-Walled Jet Engine Exhaust and Beyond: Unlocking the Potential of Blown Powder Laser Metal Deposition

As industries push the boundaries of performance, efficiency, and sustainability, advanced manufacturing technologies like Laser Directed Energy Deposition (L-DED) are stepping into the spotlight. This article showcases the development of a thin-walled jet engine exhaust using blown powder LMD, and explores how this flexible, scalable process is opening new possibilities across aerospace, oil & gas, and beyond.

Project Overview

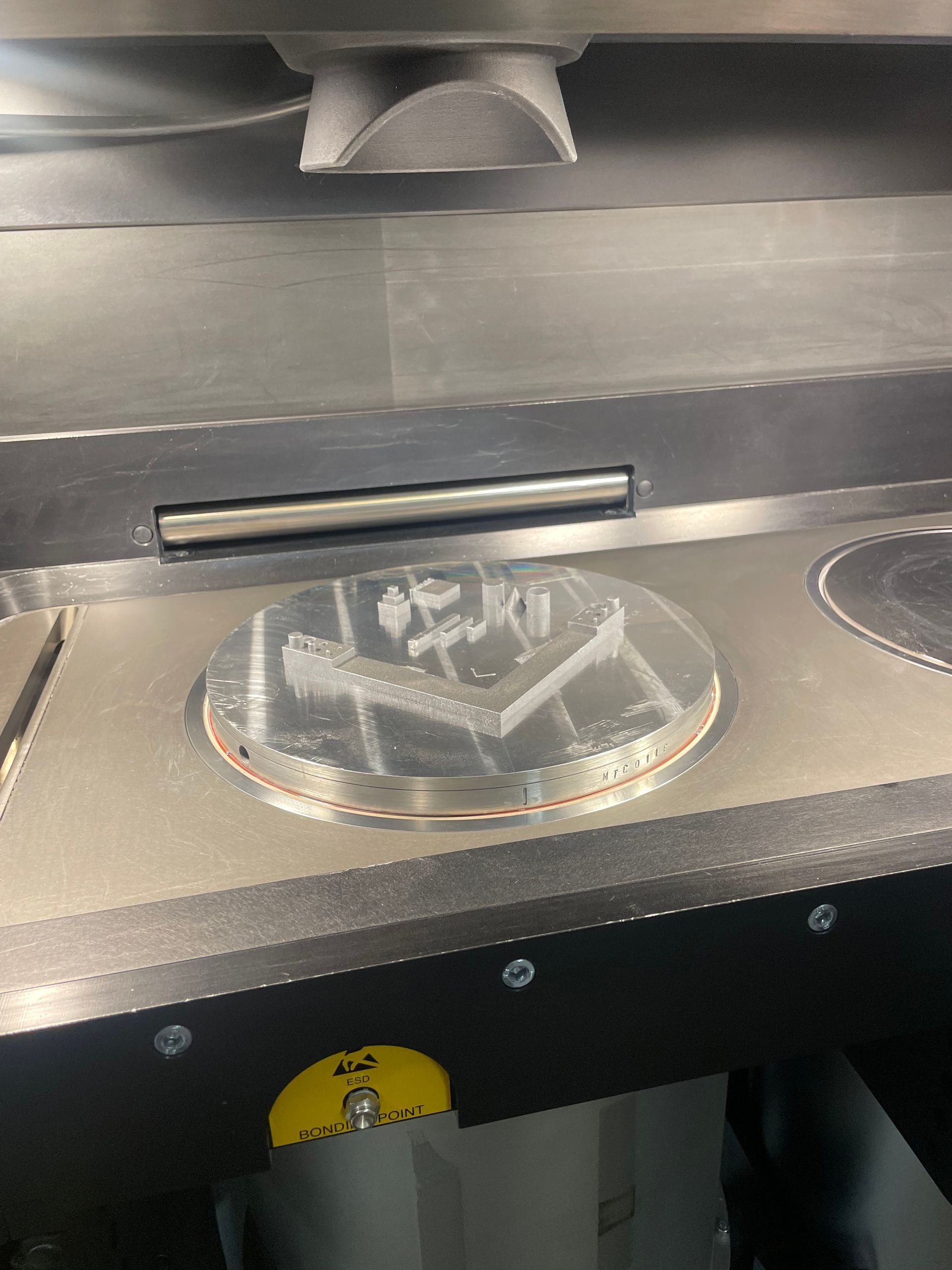

Developed for a small experimental jet engine, the component features:

- Outer Diameter: 112 mm

- Wall Thickness: 1 mm

- Length: 120 mm

- Material: Inconel 625 – a high-performance nickel-based superalloy

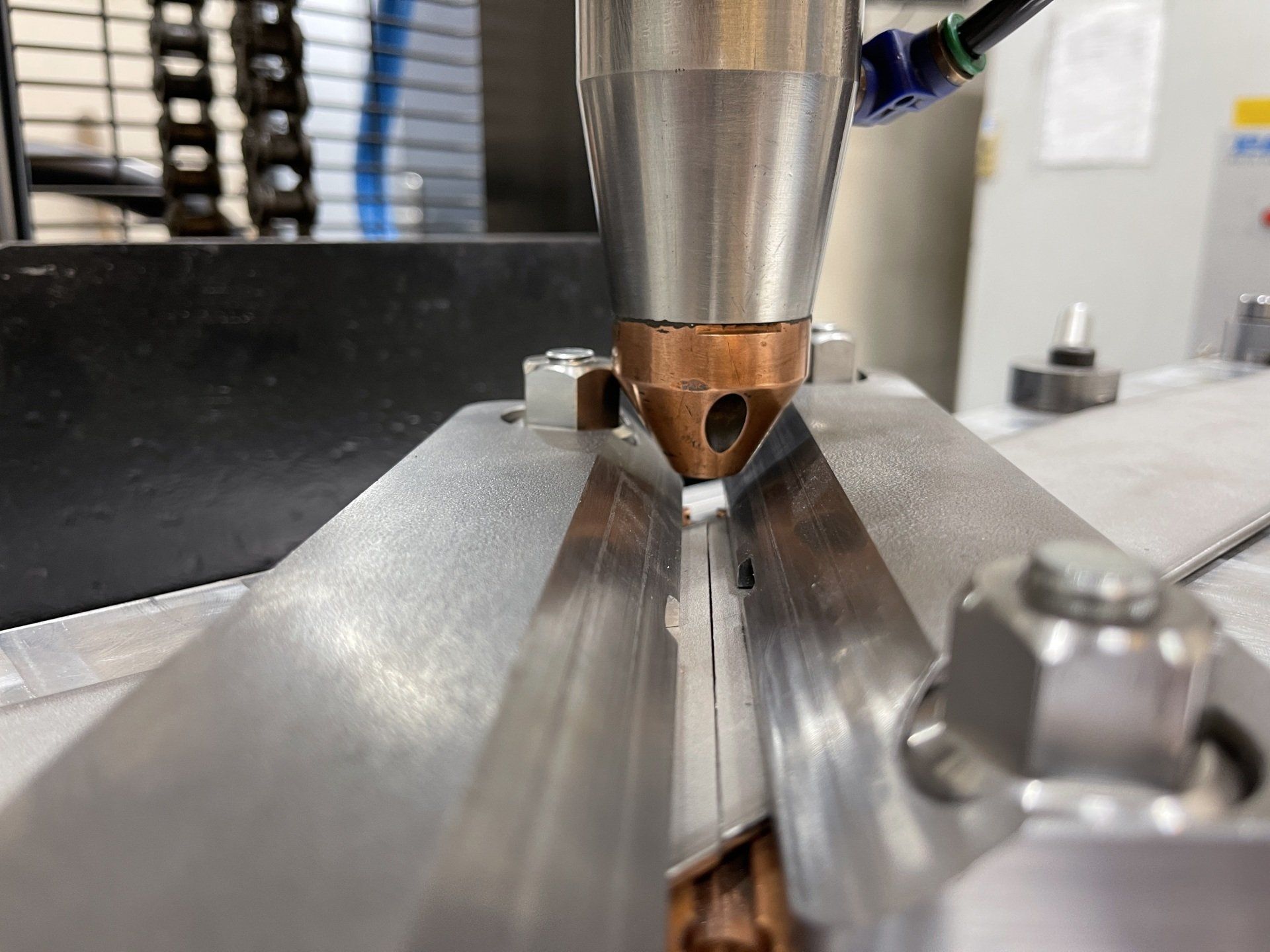

Using a single-wall spiral build strategy on a rotary tilt manipulator, the part was manufactured in just 8 hours, achieving a near-net shape with minimal post-processing.

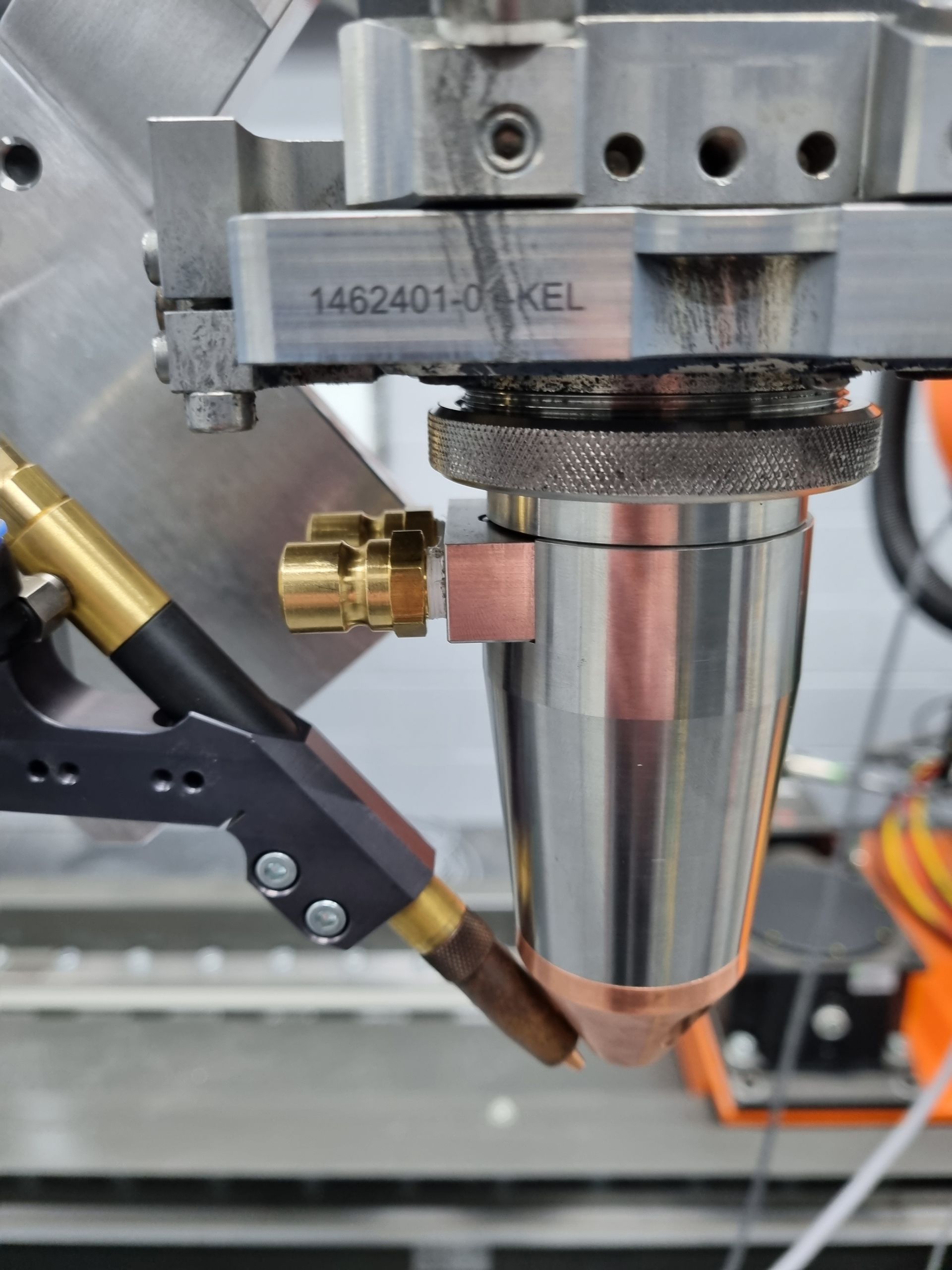

Why Blown Powder LMD?

Blown powder LMD was selected for its unique advantages:

- Low Heat Input: Ideal for thin-walled structures, reducing distortion and residual stress.

- Rapid Build Time: Significantly faster than casting or forging.

- Material Efficiency: Minimal waste due to near-net shape production.

- Design Flexibility: Geometry can be modified quickly without retooling, enabling rapid iteration and customisation.

This flexibility is especially valuable in R&D environments or when adapting to evolving customer requirements.

Scalability and Future Applications of LMD

The same process is scalable to components up to:

- 1.4 metres in diameter

- 1.5 metres in height

This opens the door to larger propulsion systems, auxiliary power units, and structural aerospace parts.

Cross-Industry Use Cases for Thin-Wall LMD

🔩 Oil & Gas

- Downhole Tools: Corrosion-resistant sleeves and housings for harsh environments.

- Valve and Pump Housings: Lightweight, pressure-resistant components.

- Heat Exchanger Shells: Thin-walled, high-surface-area structures with optimised flow paths.

✈️ Aerospace & Defence

- UAV Exhausts and Ducting: Lightweight, high-temperature components for drones and small aircraft.

- Satellite Structures: Thin-walled brackets and shielding with excellent strength-to-weight ratios.

🚗 Automotive & Motorsport

- Turbocharger Housings: High-performance, thermally stable parts.

- Battery Cooling Plates: Custom cooling geometries for electric vehicles.

🏭 Industrial Applications

- Custom Ducting: Corrosion-resistant piping for chemical and process industries.

- Tooling Shells: Lightweight moulds with integrated cooling for rapid prototyping.

🔧 Repair and Retrofit

- Component Rebuilds: Restore worn or damaged thin-walled parts with precision and minimal downtime.