Extending Service Life of Continuous Casting Belt Components with Laser Welding

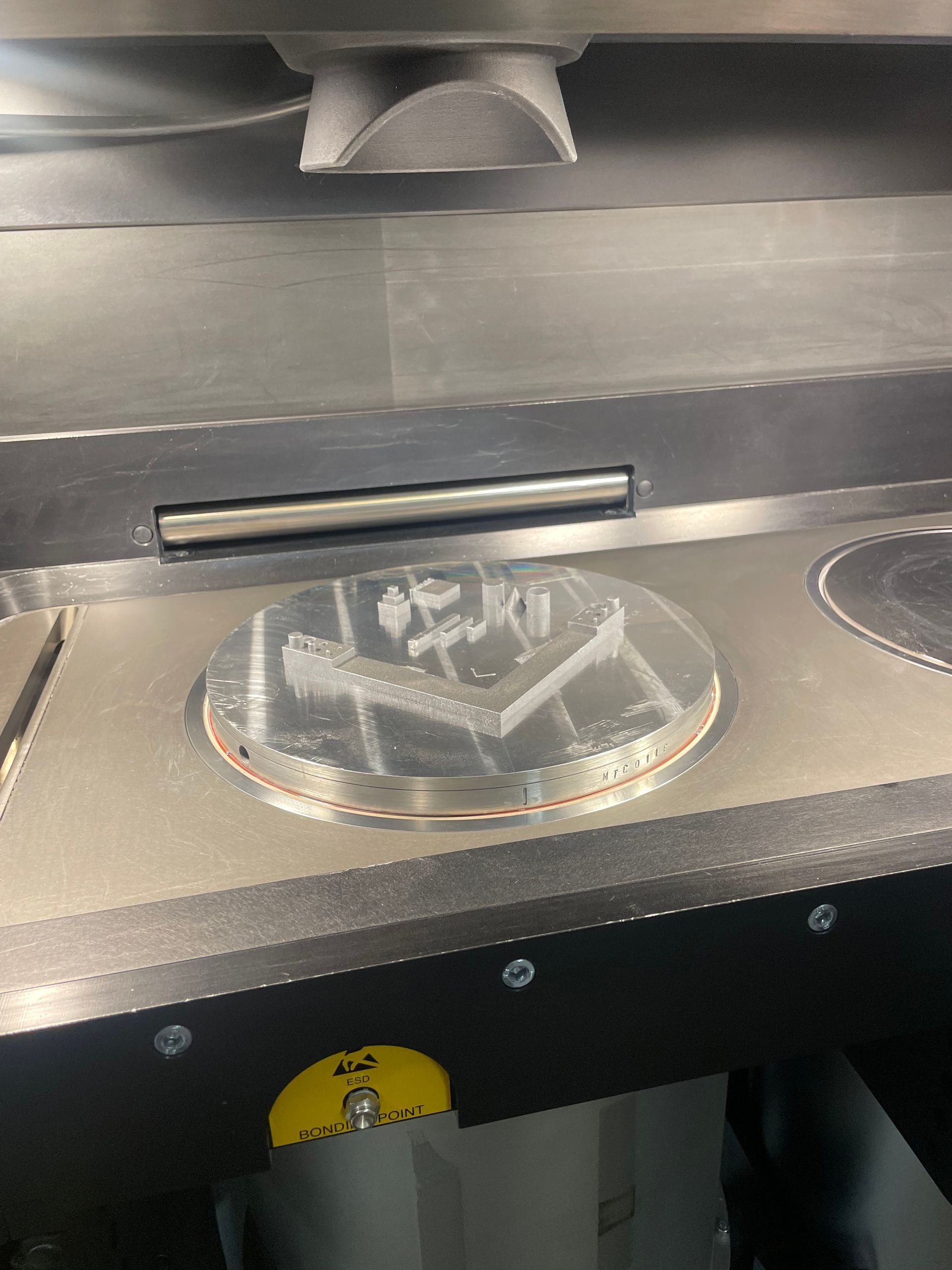

For over 10 years, Laser Additive Solutions Ltd have developed specialist Laser Welding processes for different including Nuclear, Aerospace, Electronics, Subsea etc. Across these different projects, the focus has been on various types of metals such as Stainless Steels (including Super Duplex), Nickel based (Inconel) and others. Laser Welding is one of the many advanced services offered by LAS, alongside Laser Powder Bed Fusion (Metal 3D Printing), Laser Direct Energy Deposition, Laser Hardening, and Laser Cladding.

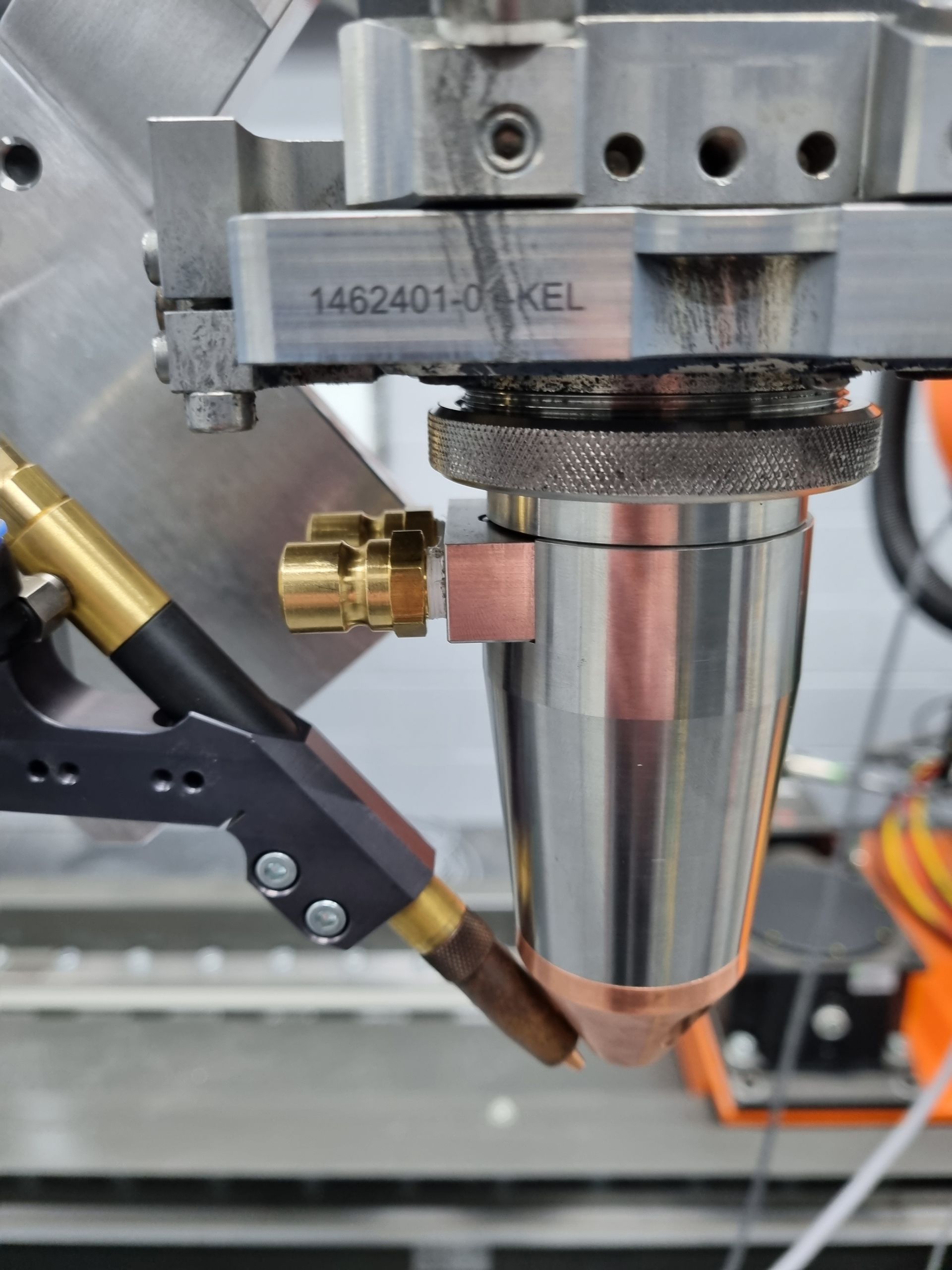

Laser Welding is a joining process that uses a focused laser beam to melt and fuse materials. Laser Welding is optimal for applications where minimal heat input is advantageous, such as high value electronics, magnets and super duplex shafts. Laser welding can be performed with or without filler material and is particularly effective for joining metals with high melting points or dissimilar materials.

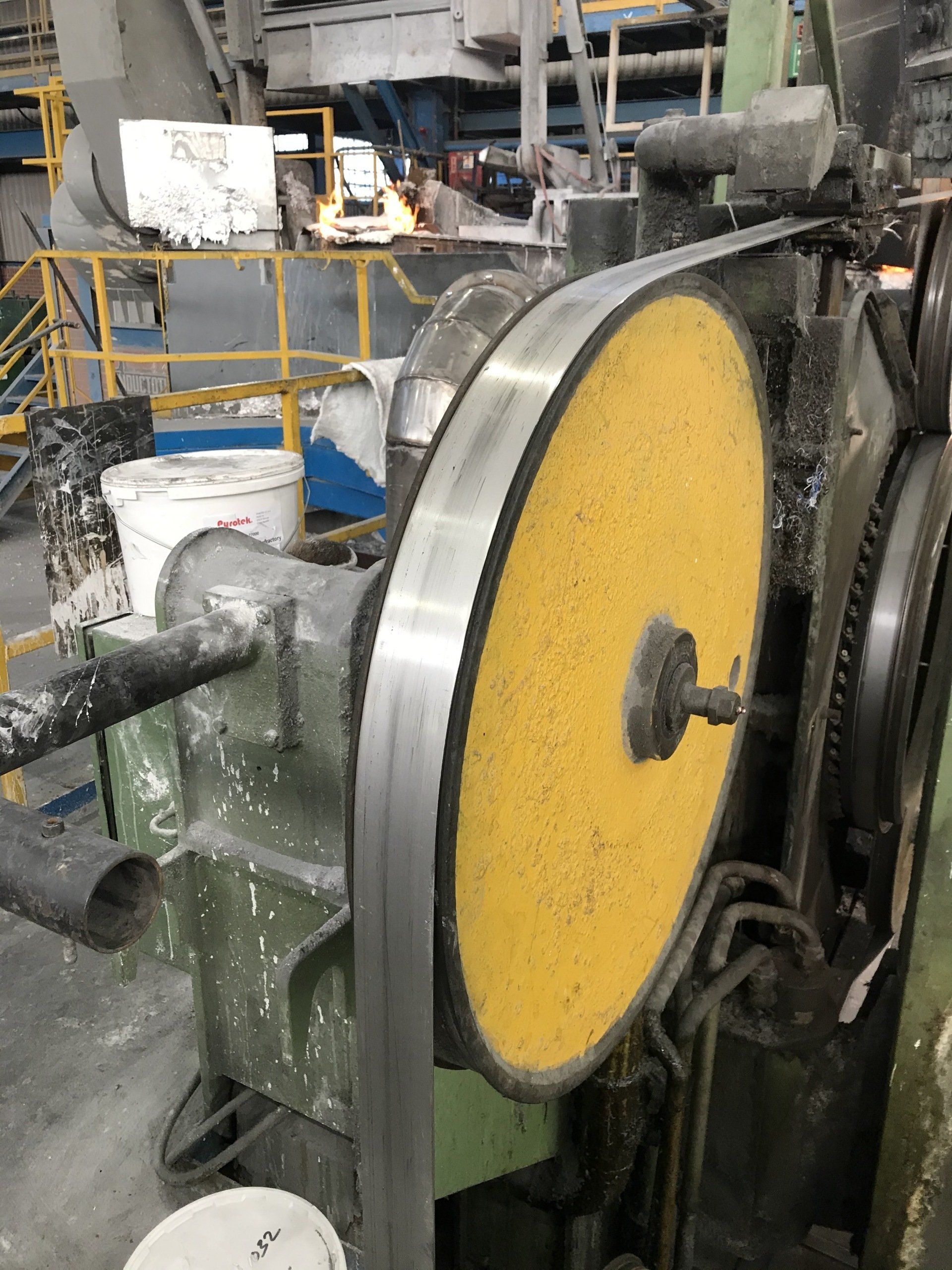

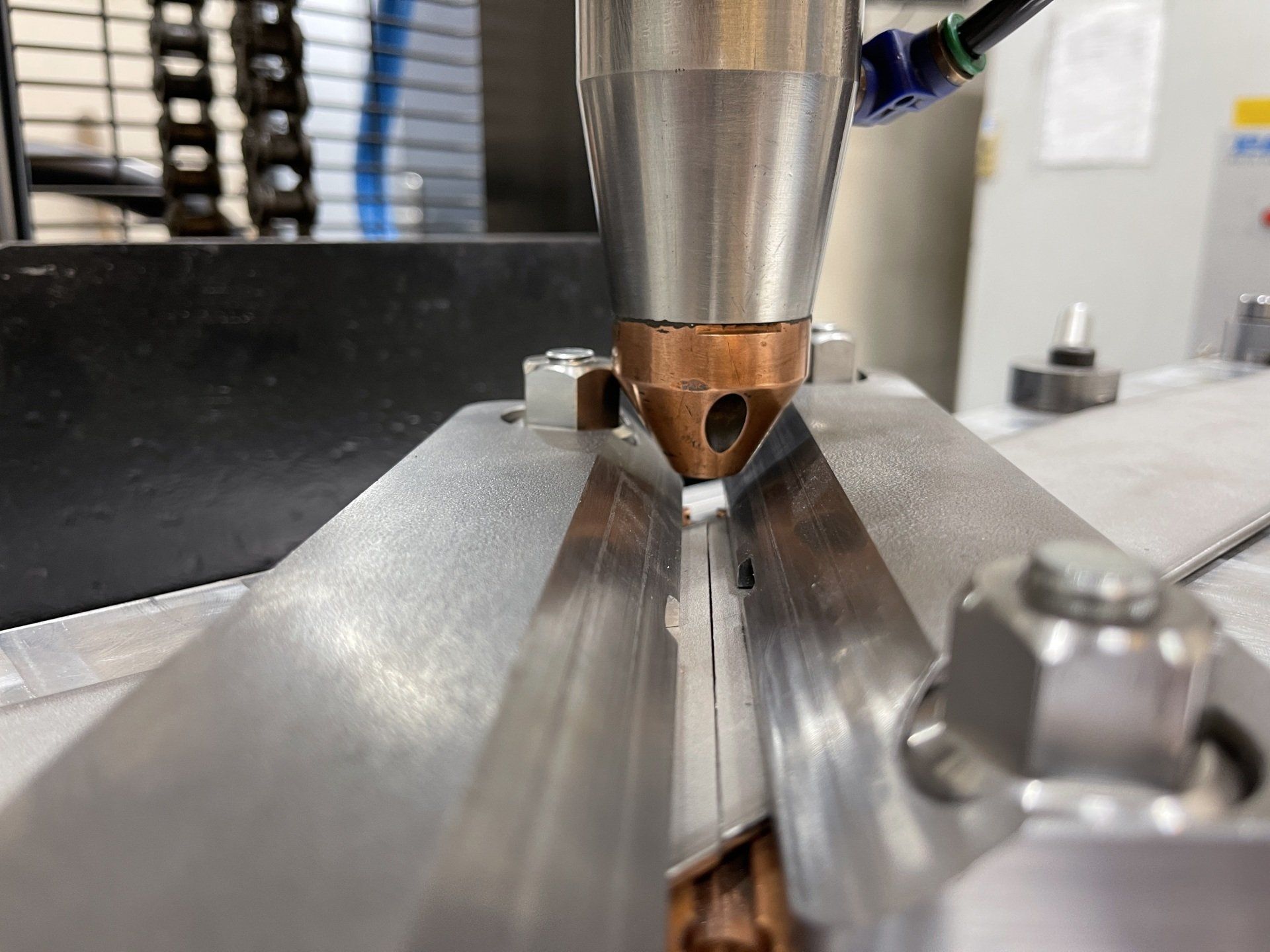

LAS was approached by a customer to address recurring issues with their continuous caster belt components. These belts, critical to the casting process, were previously joined using TIG welding. However, unreliable welding and repeated stress-induced cracking led to premature failures, unplanned shutdowns, and increased maintenance costs. The client’s goal was to improve the reliability and extend the service life of the belts without compromising performance.

After initial meetings with the client, LAS used their industrial experience to develop optimal processing parameters and improve the overall process. The results of this development was a significant performance improvement: belts manufactured using laser welding achieved an average runtime of 51.32 hours before failure, compared to 35.40 hours for TIG-welded belts. The increase of nearly 16 hours in operational life was proven over multiple belts over several months of testing. The improvements in performance were attributed to the reduction in Heat Affected Zone (HAZ) of the weld due to reduced heat input from the laser welding process compared to traditional manual welding techniques.

This improvement translated into tangible cost savings. By reducing the frequency of belt-related shutdowns and lowering maintenance demands, this resulted in the client having annual savings of approximately £125,000. In addition to the financial benefits, laser welding enhanced production stability and reduced downtime, contributing to a more efficient and reliable operation.

LAS is happy to assist with all laser welding enquiries, regardless of material or application. Please don’t hesitate to contact us today to discuss your requirements.

Contact Us