Simply put… Yes. It is possible to 3D Print Pure Tungsten using Laser Direct Energy Deposition. Although, there remains some limitations that need to be overcome.

Why Pure Tungsten?

Tungsten is well known for its suitability for nuclear fusion reactors, MRI scanners and radiation shielding. Majority of the applications of tungsten stem from its high melting point (above 3000°C) and excellent X-Ray/Gamma Ray absorption.

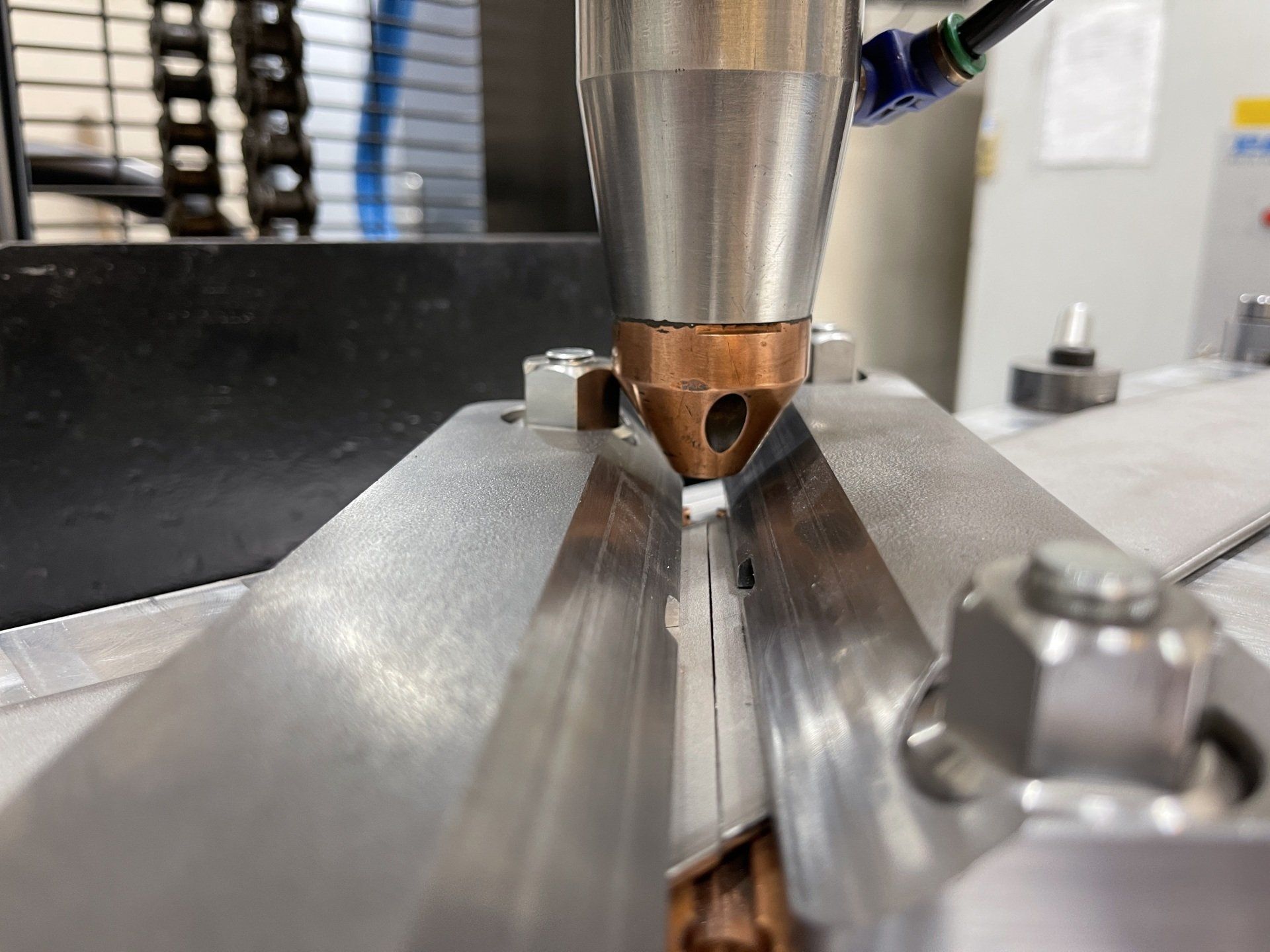

One of Tungsten’s most promising applications is inside Nuclear Fusion reactors to provide a lining to contain heat and radiation. Despite the encouraging future for large scale tungsten components, the issue is still how best to manufacture these parts. Typically, Tungsten is tricky to machine, and this comes with limitations for designing Tungsten components. So, the potential to have cooling channels within the reactor components is almost impossible without Additive Manufacturing.

An alternative to machining Tungsten...

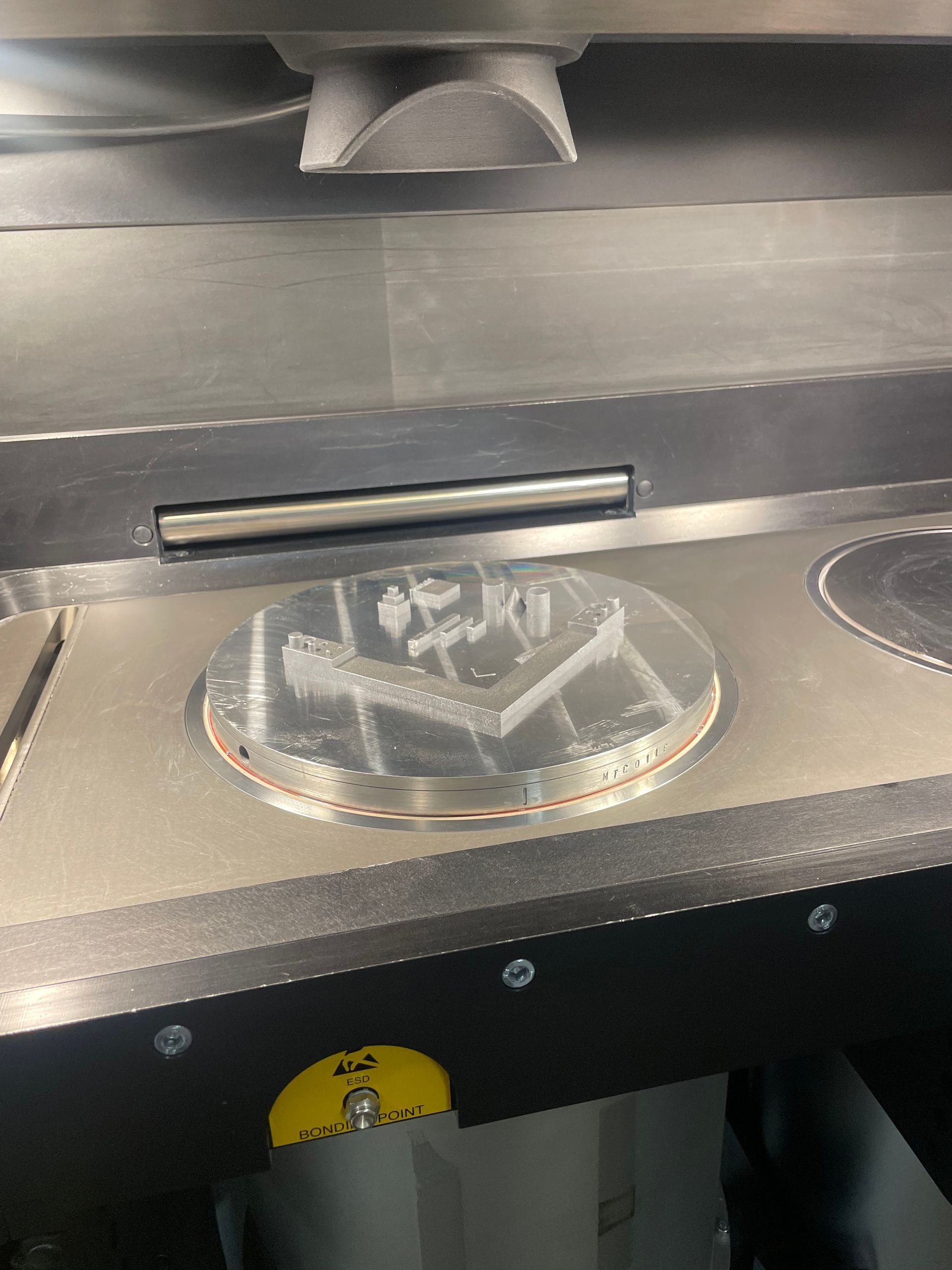

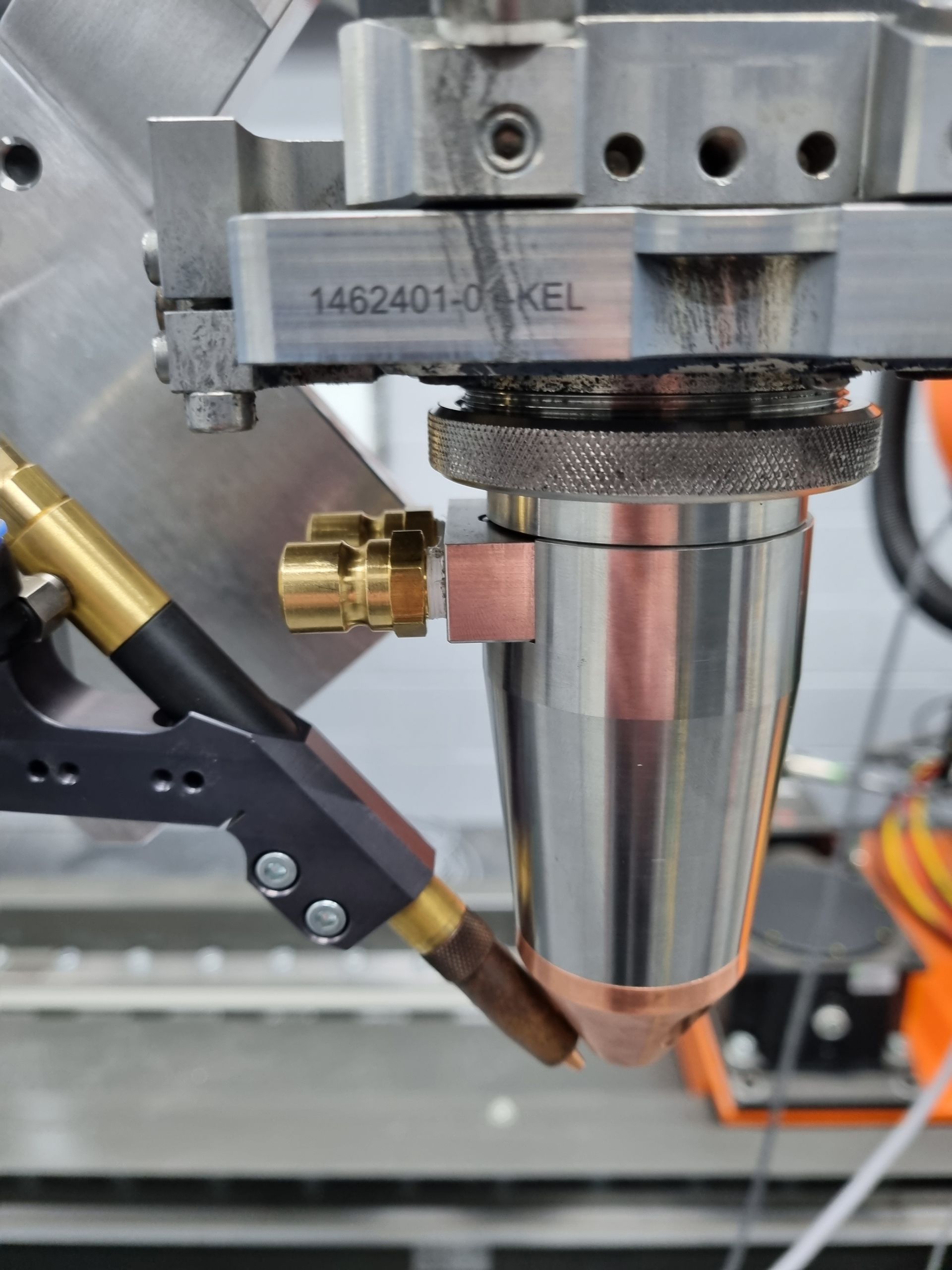

Laser Direct Energy Deposition, L-DED, is a type of Additive Manufacturing technology that feeds metal powder (or wire) into the path of a moving laser beam so that a component can be built up. The laser processing head is mounted onto a multiple-axis robot which improves versatility compared to other metal additive manufacturing methods.

Laser Additive Solutions, LAS, have recently completed a research project developing high quality parameters to additively manufacture pure Tungsten. The project ‘AM4F’ (Additive Manufacturing for Fusion) investigated the effect of ultrasonics and inert processing environments on the properties of Tungsten Tiles. AM4F showed promising early results for Additively Manufacturing Tungsten parts and highlighted the capabilities of Laser Additive Solutions innovative equipment.