Introducing Project TITAN:

3D PRINTING TITANIUM BICYCLE COMPONENTS

Laser Additive Solutions Ltd (LAS) is excited to announce Project TITAN, an innovative project to develop titanium bicycle components using Additive Manufacturing (AM) technology. With a focus on Laser Powder Bed Fusion (L-PBF), Project TITAN aims to design and develop high-performance Titanium pedals. The project is, also, focused on developing optimised Titanium parameters to ensure components are cost-effective, whilst ensuring quality.

TITAN is funded as part of Innovate UK Design Foundations: Repairability competition, is funded by the UKRI, delivered by Innovate UK.

Can you 3D Print Titanium?

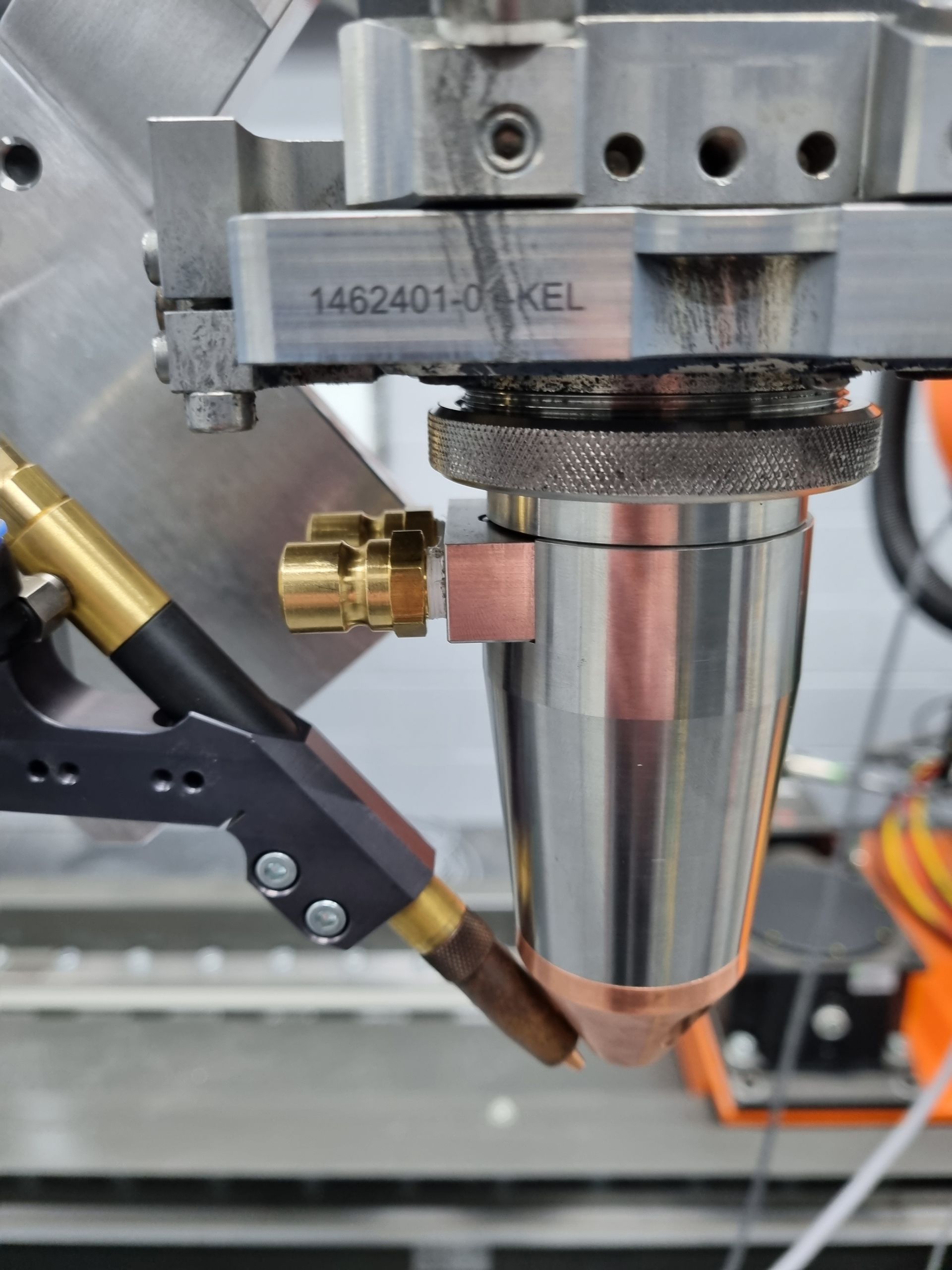

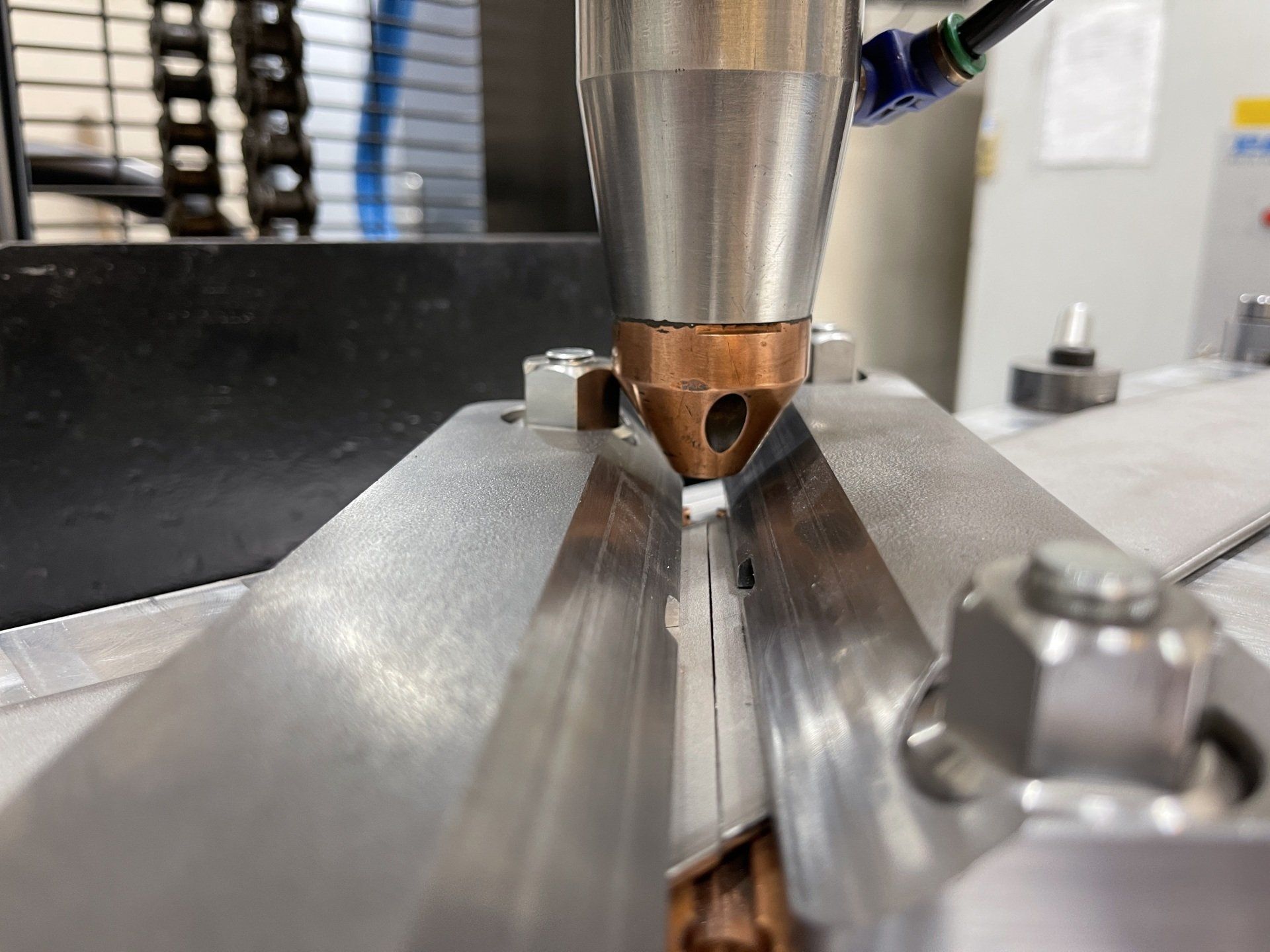

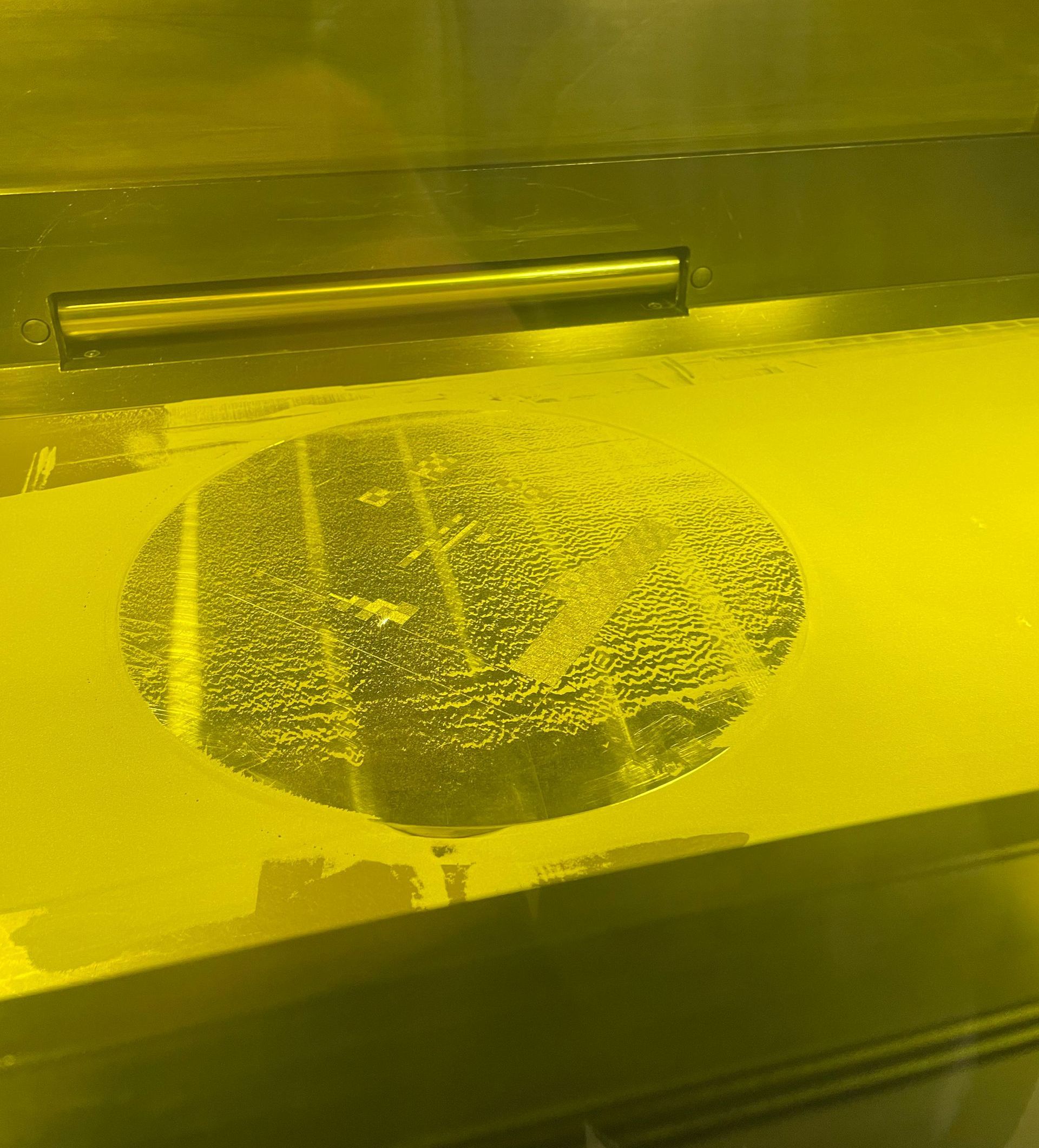

LAS 3D Prints Titanium using a technique called Laser Powder Bed Fusion. This is when a thin layer of powder is spread across the build envelope and selectively melted by a laser (hence the alternative technology name of Selective Laser Melting). The build plate will then drop lower into the cylinder and another layer of powder will be spread. This process will continue until the full height of the part has been reached.

Why 3D Print Titanium Bicycle Parts?

Titanium is highly valued in the Bicycle Industry due to its good strength-to-weight ratio and lightweight properties. However, traditional machining of titanium is challenging, often limiting design flexibility. Therefore, 3D Printing Titanium components enables lower cost parts, complex designs and significant weight reductions.

What will Project TITAN achieve?

Project Titan aims to

- Developing optimised Ti64 Parameters for applications across all industries.

2. Designing custom Titanium bike pedals for Individuals/Business

3. Create a sustainable process for recycling old Titanium parts.

How can you get involved?

Project Titan includes a Customer Design Board, CDB. The board will advise on the design, review prototypes and receive a free pair of Titanium Bicycle Pedals at the end of the project. So, if you have an interest in Cycling, sign up with the link below.

Join the Customer Design Board Now