Discover the capabilities of Laser Welding in Modern Manufacturing

What is Laser Welding?

Laser welding is a precision joining process that uses a focused laser beam to fuse materials, typically metals, creating strong, durable bonds. Its concentrated heat source enables use for thin materials and produces deeper welds in thicker materials. Laser welding is favoured for its accuracy, minimal distortion, and versatility across various industries, including automotive, aerospace, and electronics, where precise and reliable welds are crucial for component fabrication and assembly.

How does Laser Welding work?

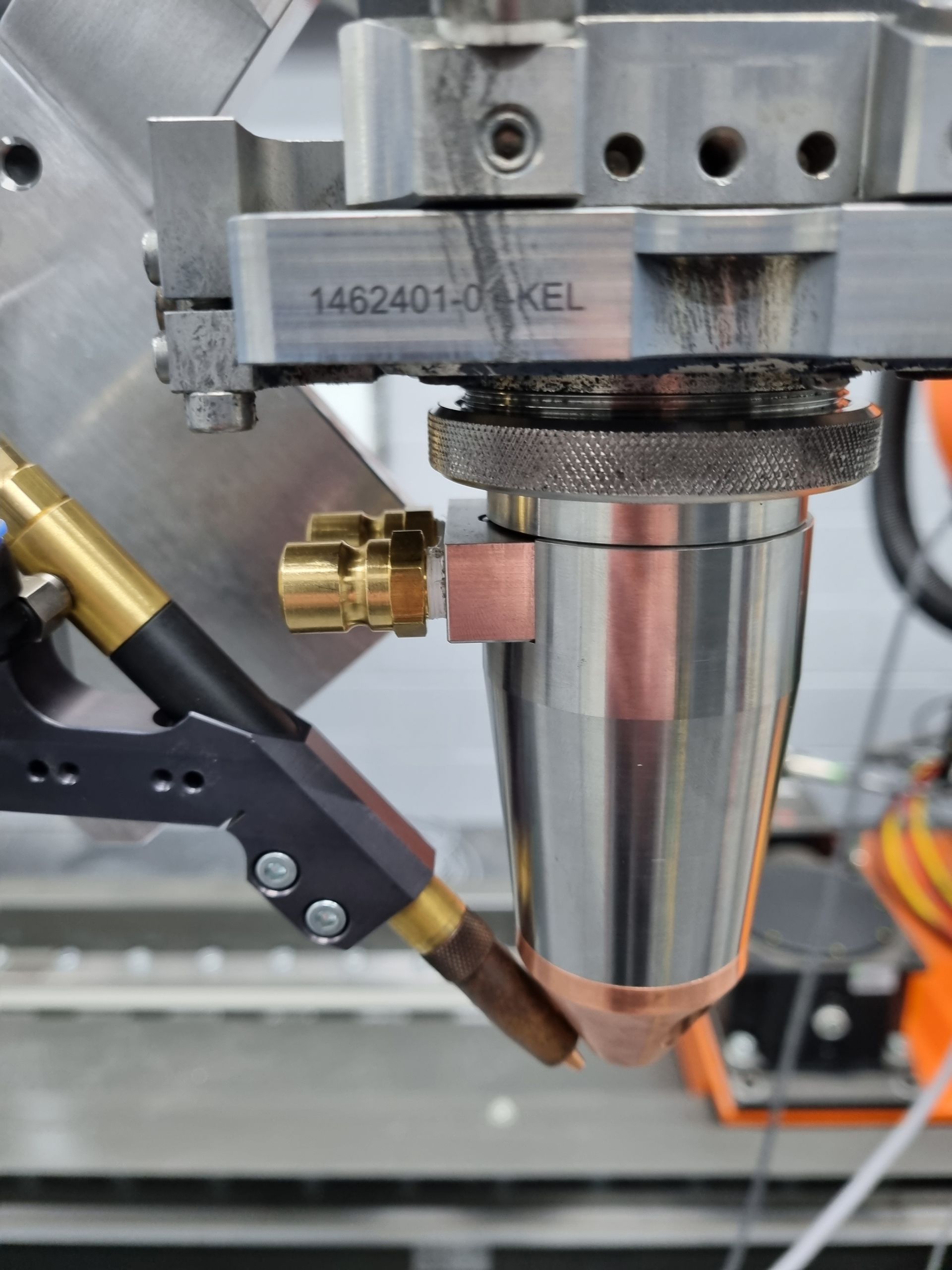

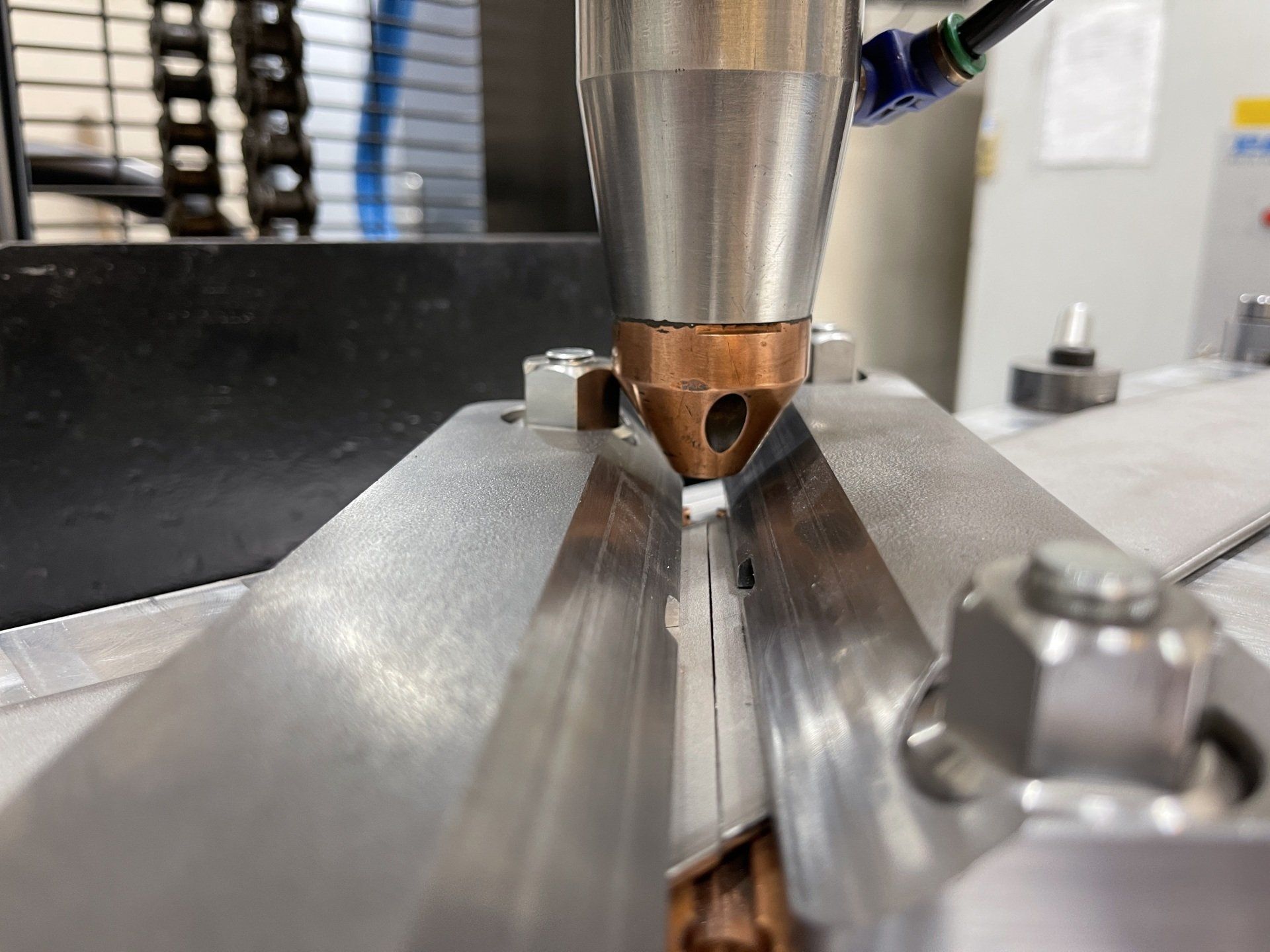

The process begins with a high-powered laser beam generated by a laser source. This beam is then directed through focusing optics that concentrate its energy into a small, precise spot. When the beam makes contact with the material surface, it rapidly heats and melts the substrate, creating a weld pool. As the material cools, a strong, durable bond is formed between the joined pieces.

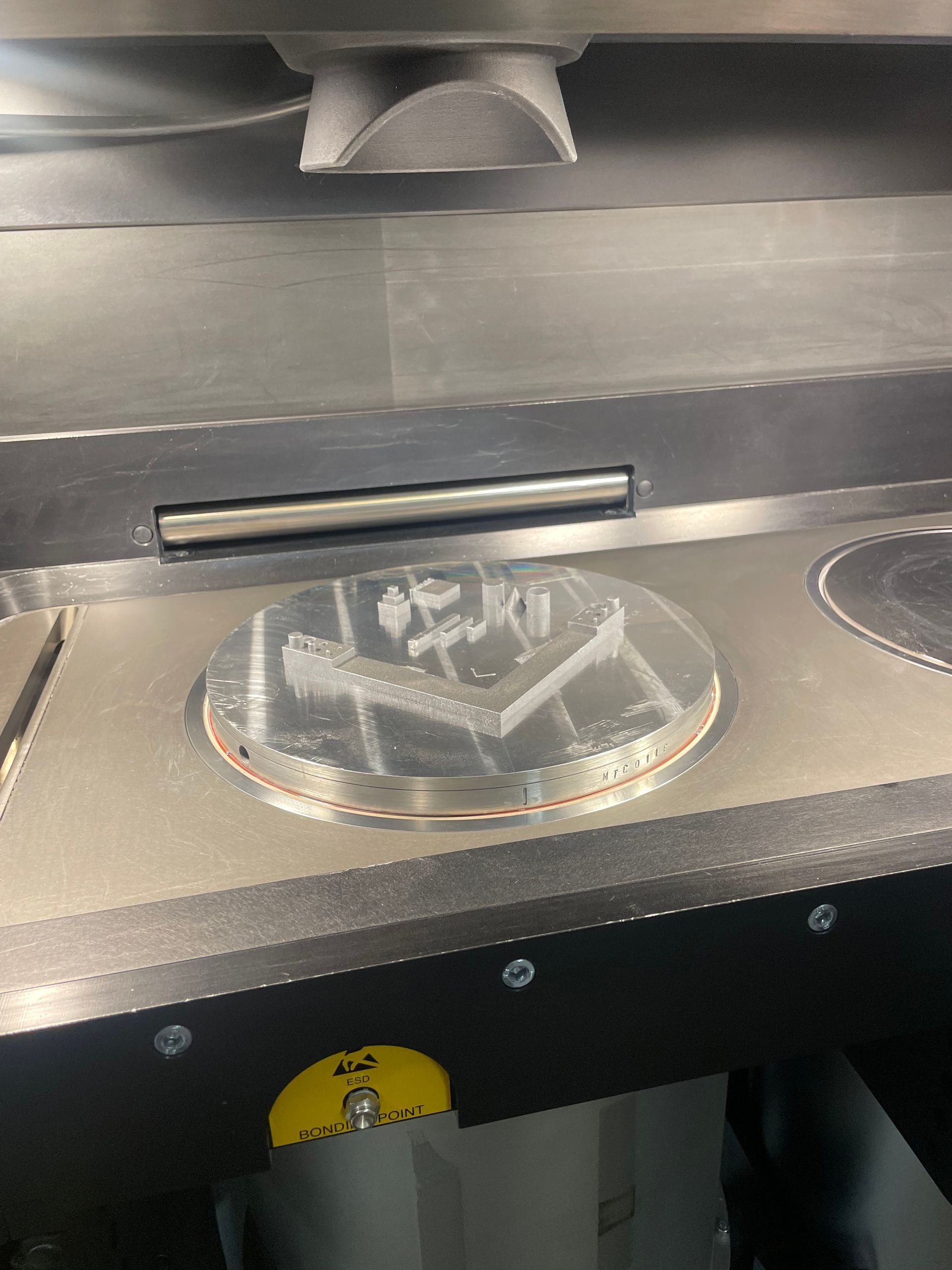

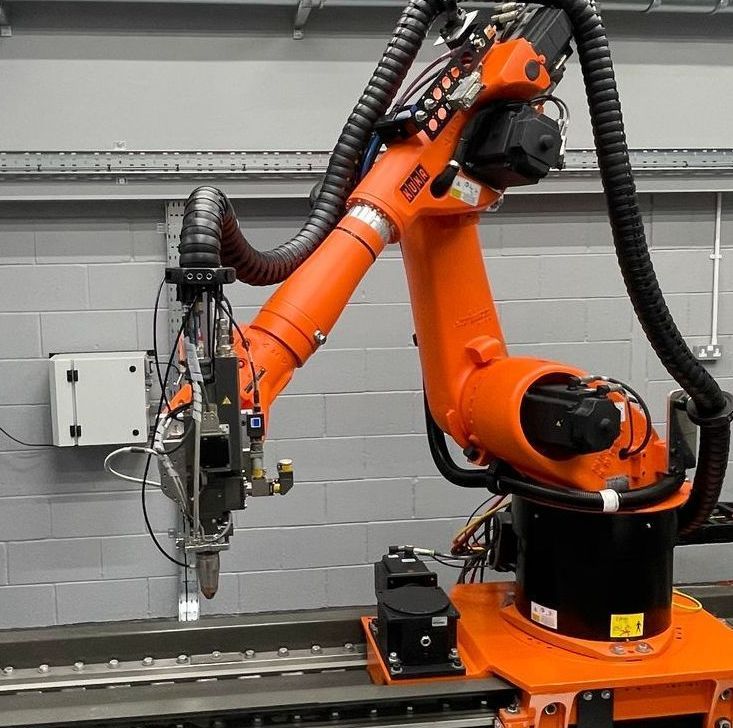

Figure 1: Laser Welding Machine at Laser Additive Solutions

What are the applications of Laser Welding?

Laser Welding Application for Automotive

Laser welding is widely used in automotive manufacturing for joining components such as body panels, chassis parts, exhaust systems, and engine components. Its ability to produce strong, precise welds at high speeds makes it ideal for mass production processes.

Laser Welding Applications for Aerospace

In the aerospace sector, laser welding is utilised for assembling aircraft components, including fuselage sections, engine parts, and turbine blades. Its capability to weld lightweight materials like aluminium and titanium with minimal distortion is particularly advantageous.

Laser Welding Applications for Medical

The medical industry utilizes laser welding for assembling medical devices and equipment such as surgical instruments, implants, and diagnostic devices. Laser welding stands at the forefront of medical device manufacturing, leveraging its unparalleled precision and delicacy to craft intricate and crucial components.

Laser Welding Applications for Oil and Gas

Laser welding in the oil and gas industry is crucial for pipeline fabrication and repair, subsea equipment manufacturing, pressure vessel fabrication, drilling equipment production, and corrosion protection. Its precision welds ensure structural integrity in pipelines and subsea equipment, while its corrosion-resistant cladding extends the lifespan of critical components. With minimal heat input and precise control, laser welding delivers durable welds for components subjected to harsh environments, enhancing safety and efficiency in oil and gas operations.