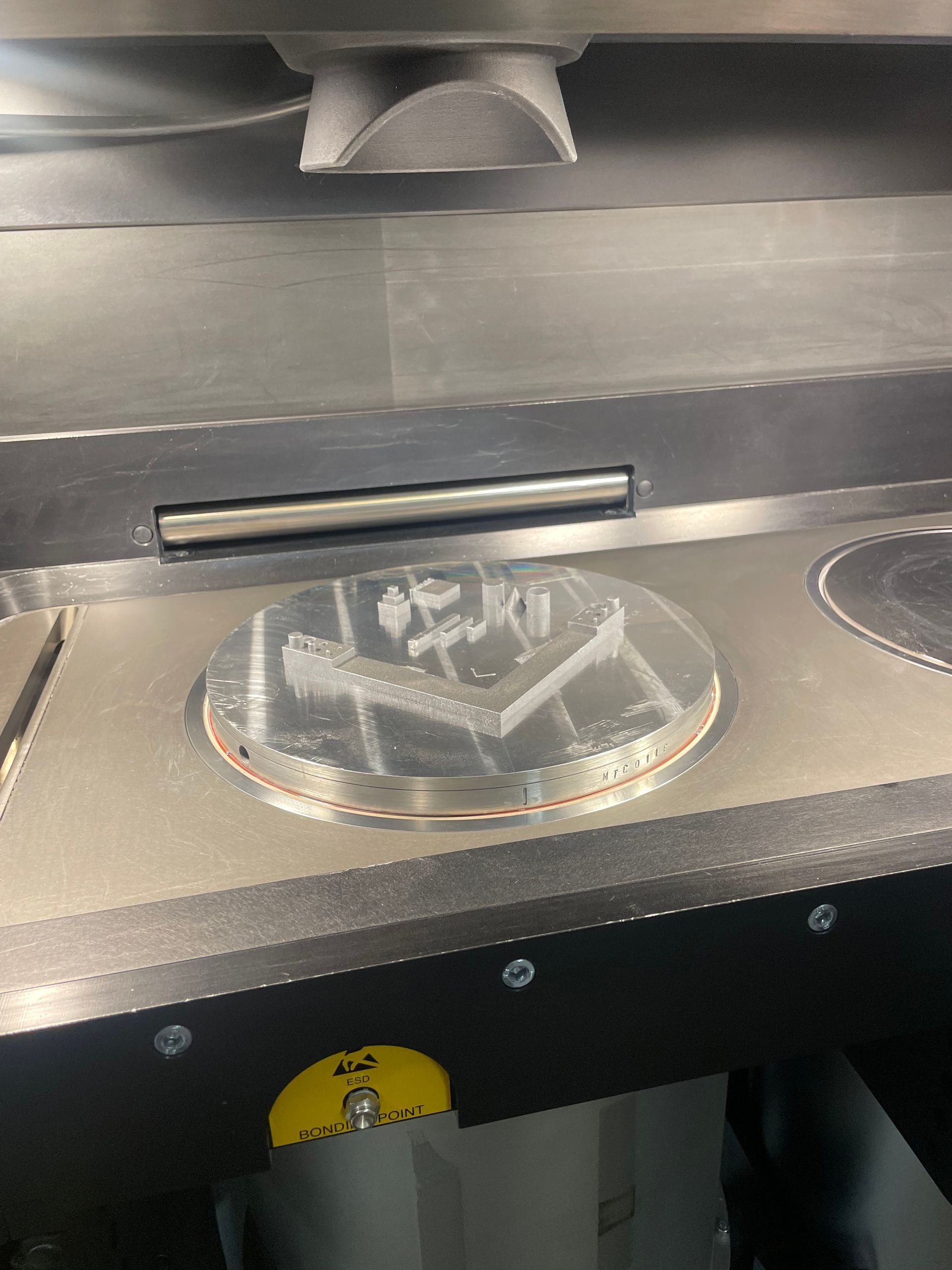

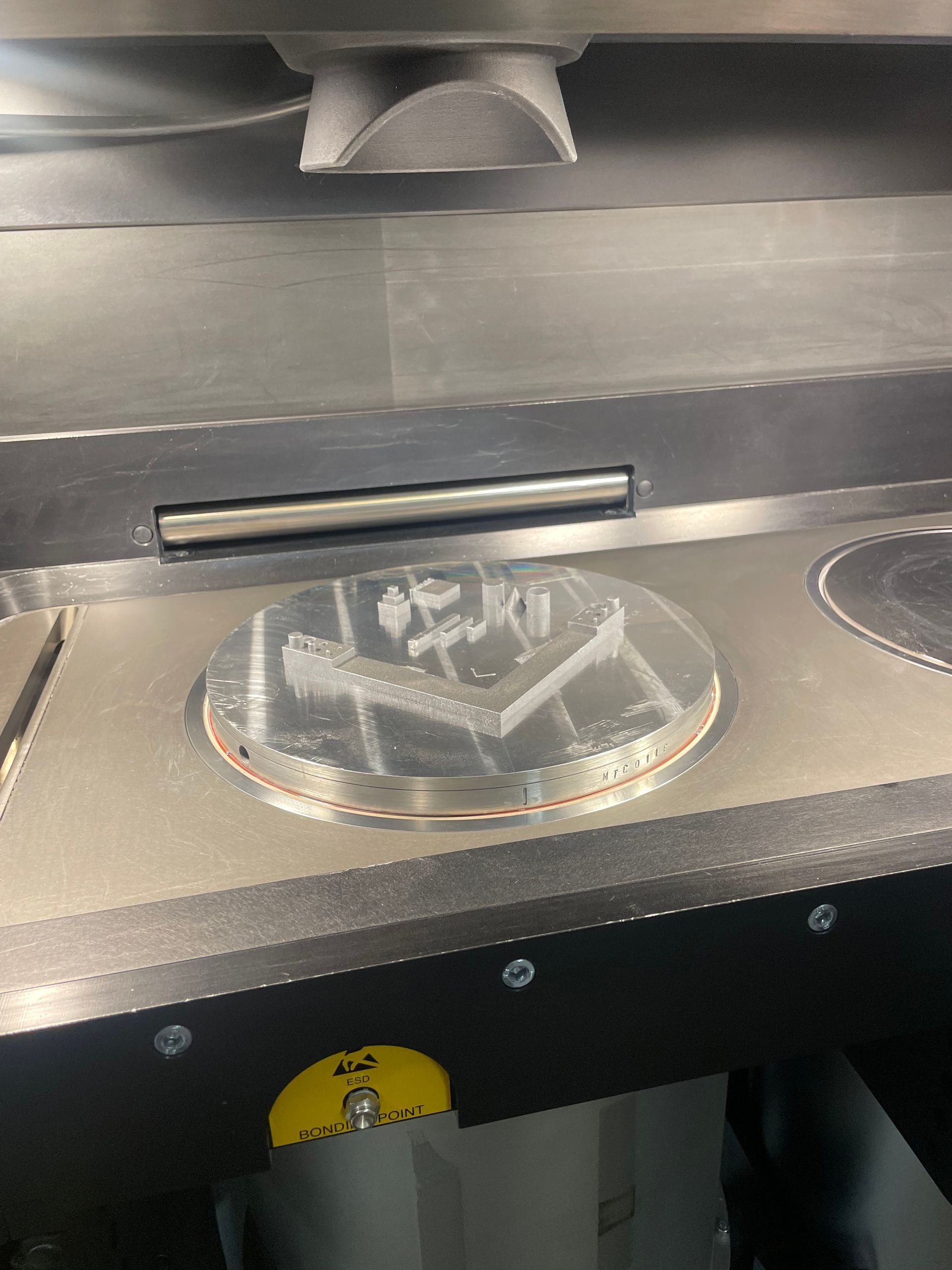

EXPLORE LASER ADDITIVE SOLUTIONS ADVANCED METAL 3D PRINTING MACHINE

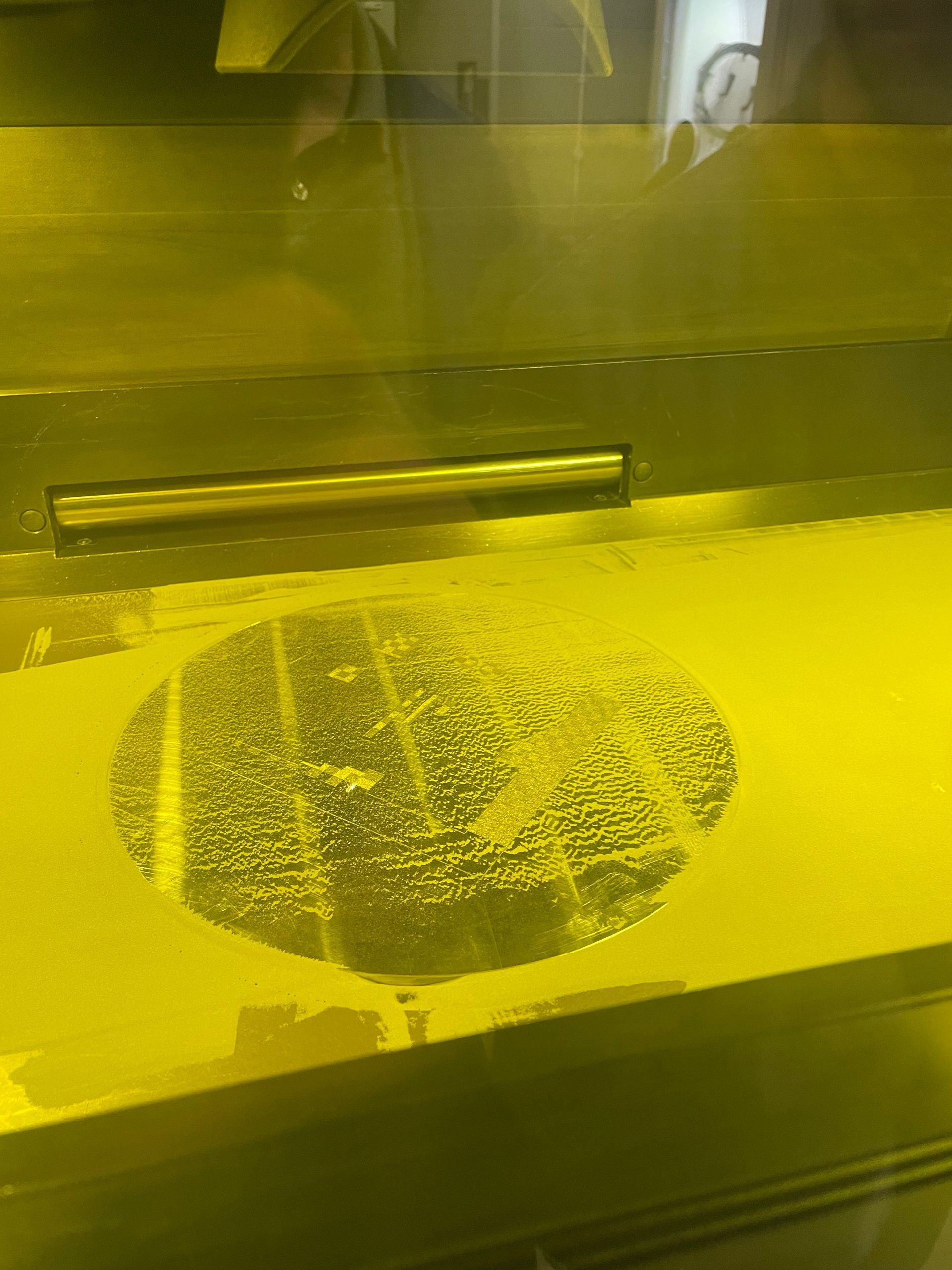

Laser Additive Solutions introduces a TRUMPF TruPrint 3000 SLM machine, expanding their advanced manufacturing capabilities beyond two Laser Direct Energy Deposition cells. This integration marks a new era for our business, enhancing our capacity to include Laser Powder Bed Fusion technologies. With the proven expertise from their existing Laser Direct Energy Deposition cells, Laser Additive Solutions continues to innovate in additive manufacturing, providing efficient solutions for complex and customized part production.

What is Laser Powder Bed Fusion?

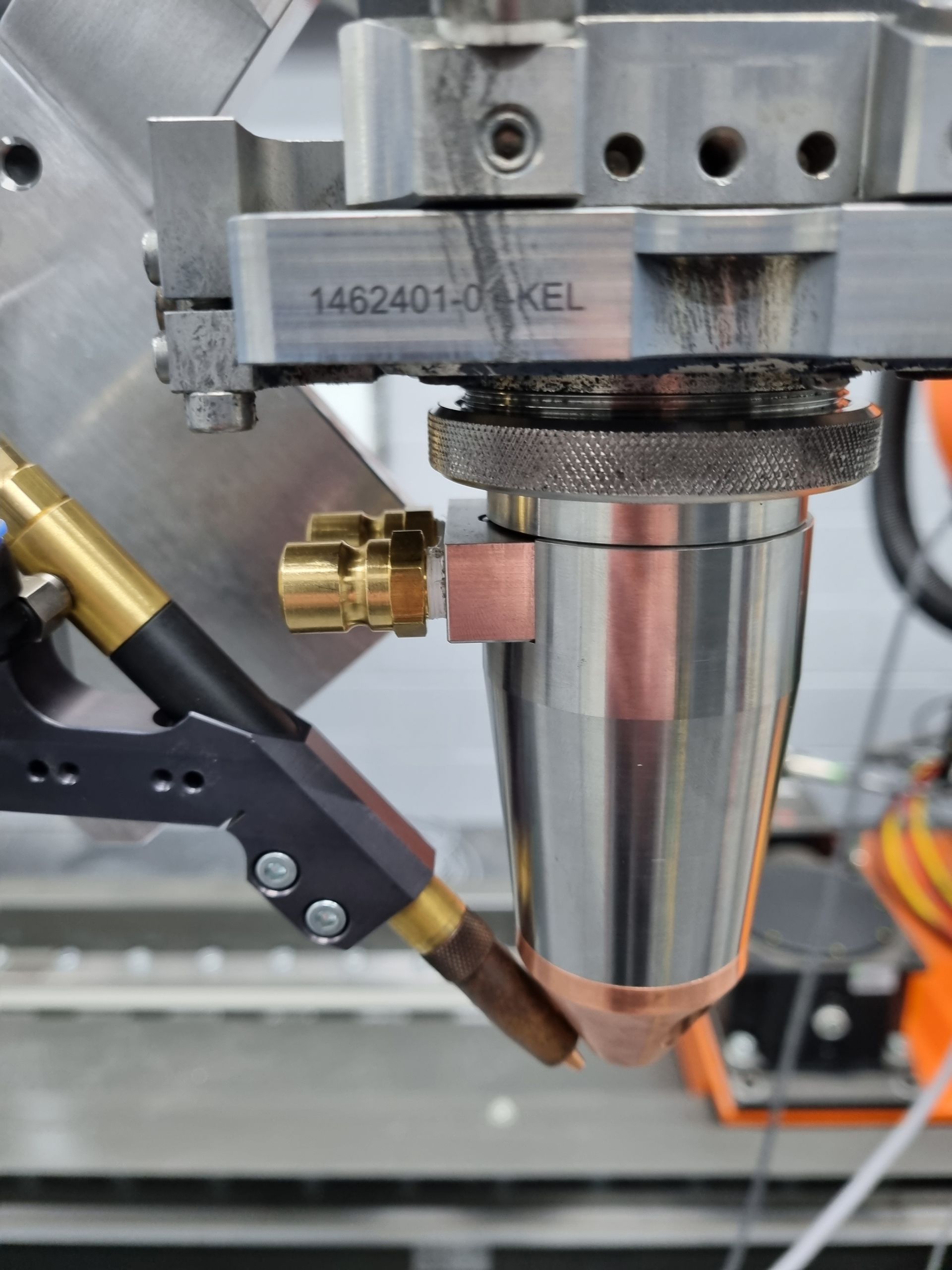

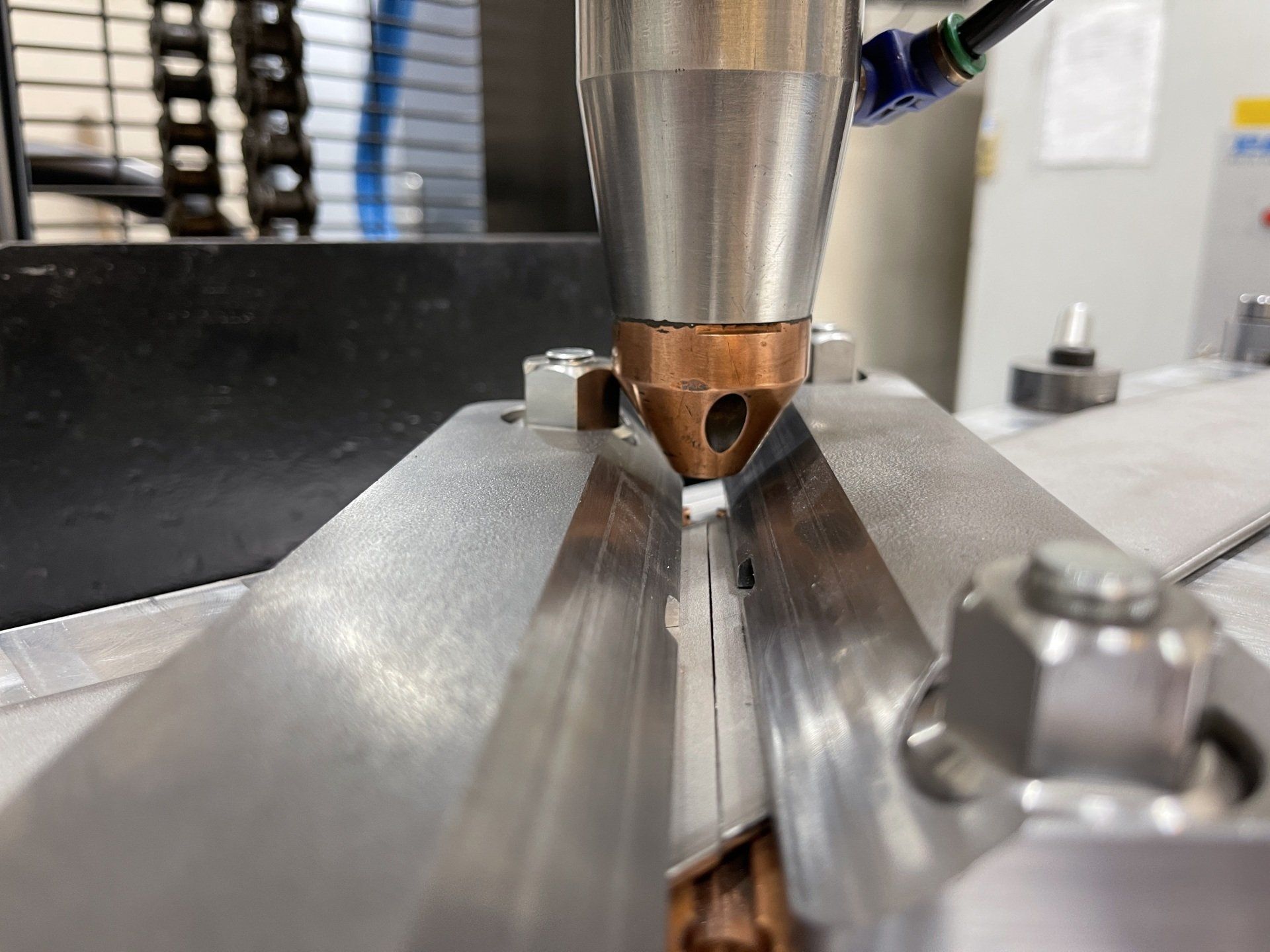

Laser Powder Bed Fusion (LPBF) is an additive manufacturing technique where a laser selectively melts layers of powdered material, typically metals, to create intricate three-dimensional objects. A computer-controlled system precisely deposits and fuses the powder layer by layer, forming complex and customized structures with high precision.

Advantages of 3D Printing with L-PBF

LPBF is widely used in aerospace, healthcare, and automotive industries for rapid prototyping and manufacturing of intricate components, offering advantages such as design flexibility, reduced material waste, and the ability to produce geometrically complex and lightweight parts with excellent mechanical properties.

What Materials can be 3D printed?

Typical materials that can be 3D Printed are:

- Steel (Including Stainless Steel)

- Aluminium

- Copper

- Cobalt Chrome

- Titanium

- Tungsten (and Tungsten alloys)

- Nickel-based Alloys

For a quick tour of the equipment: