AN ALTERNATIVE TO MACHINING INCONEL 718: WIRE DIRECT ENERGY DEPOSITON

What is Inconel 718?

Inconel 718 is a high strength nickel-based superalloy. It is typically used due to its exceptional heat resistance, corrosion resistance and mechanical properties. It is commonly used in the Aerospace Industry.

What are the challenges with machining Inconel 718?

Traditional manufacturing processes often face challenges in achieving intricate geometries and optimising material usage. Inconel is a particularly expensive material to purchase and slow to machine due to it work hardening when cut with machine tools. Wire DED offers an alternative to buying large blocks of material and generating lots of waste.

Advantages of Wire Direct Energy Deposition for Inconel 718.

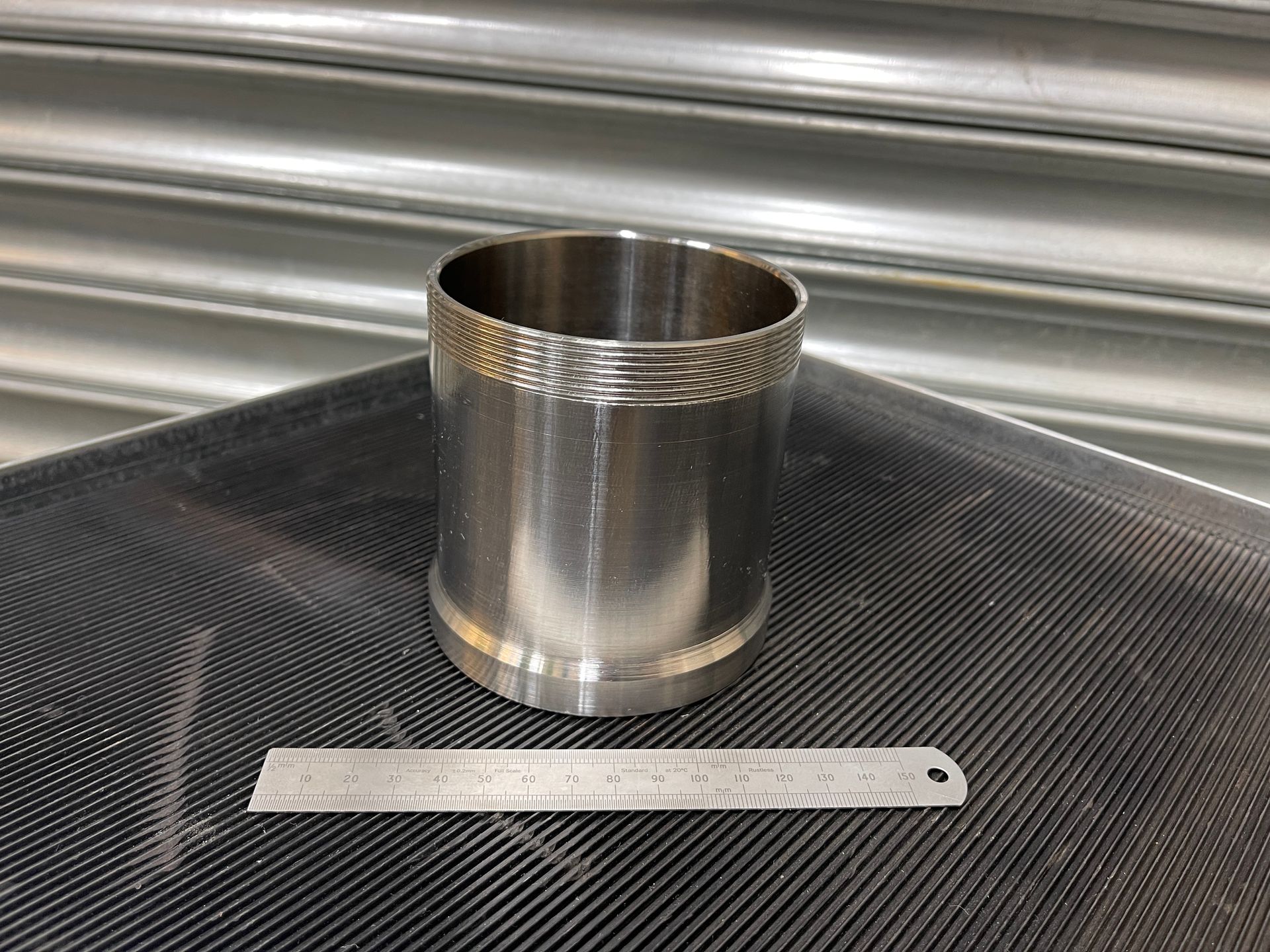

Wire Direct Energy Deposition offers a low waste solution for manufacturing Inconel 718 parts with lower costs compared to machining particularly for thin-walled parts where machining required is excessive and expensive. Wire DED also offers the opportunity to consolidate the supply chain of Inconel 718 from varying sizes of bar and plate to just one form which is Wire therefore reducing supply chain issues along with procurement challenges. It also allows parts to be quickly manufactured to a near net shape and then finish machined/ground with only around 1mm material being required to remove. Wire DED is not limited to manufacturing new parts, but can also be applied to repairing existing parts.

How does Wire Direct Energy Deposition Work?

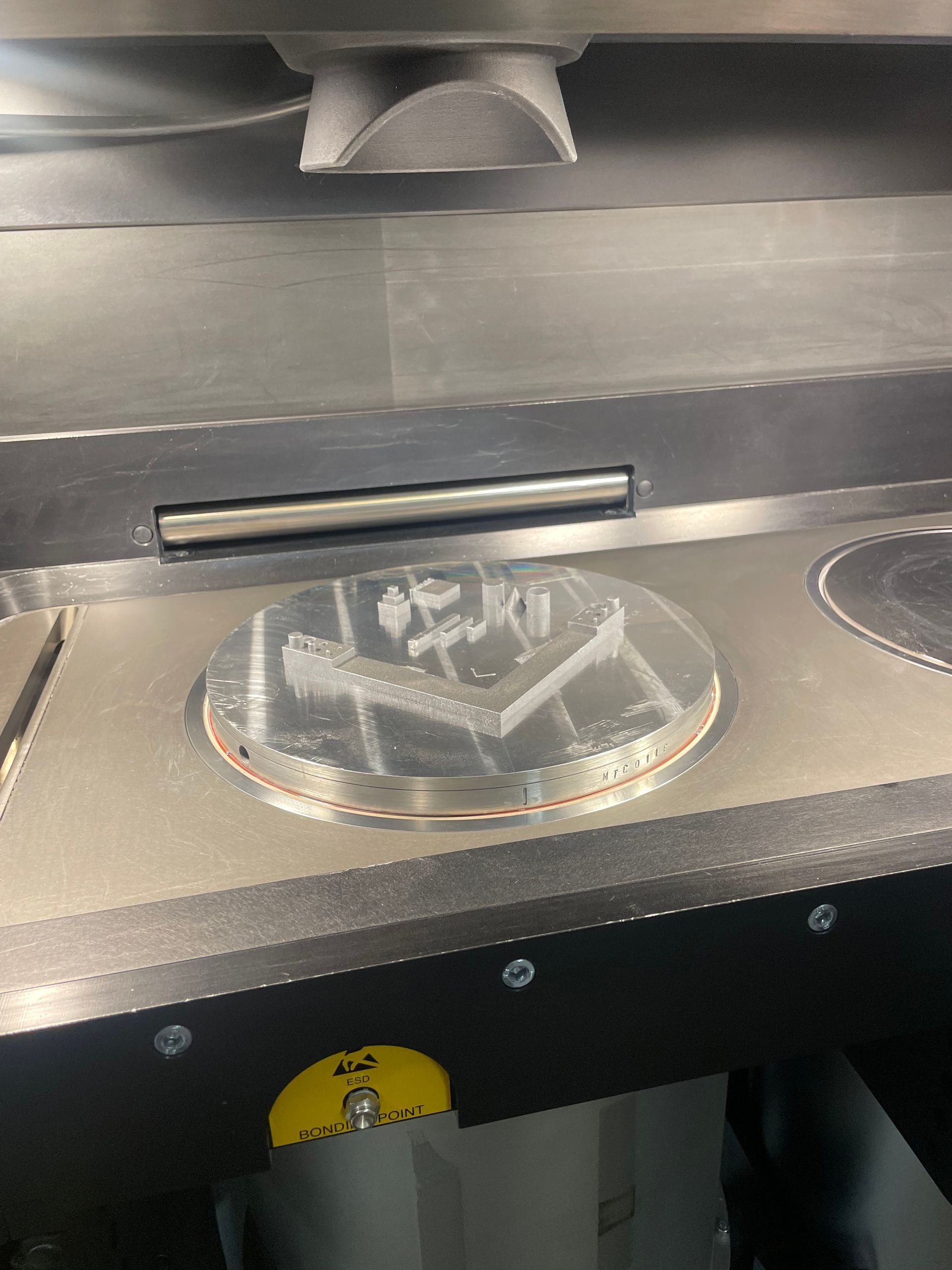

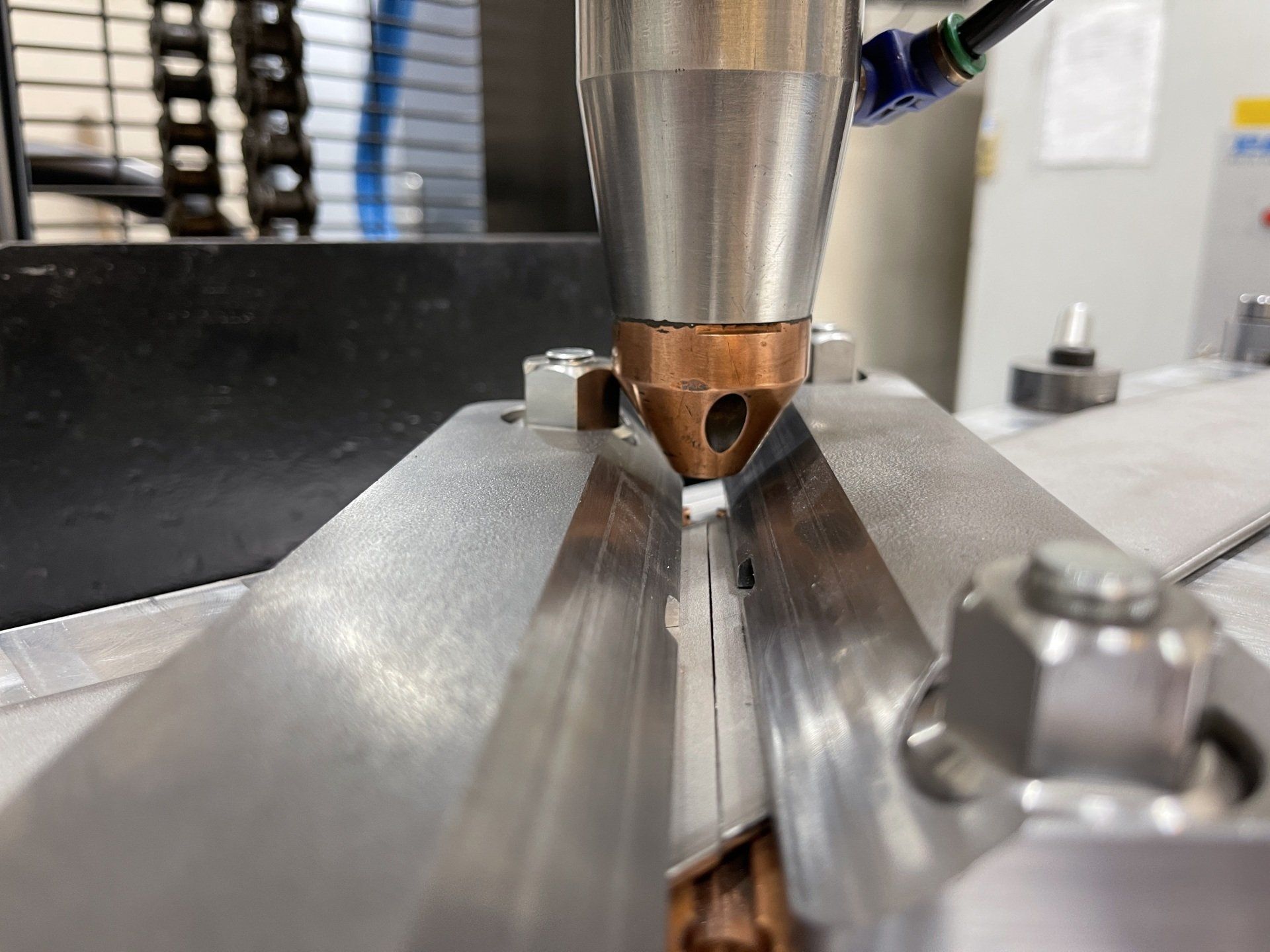

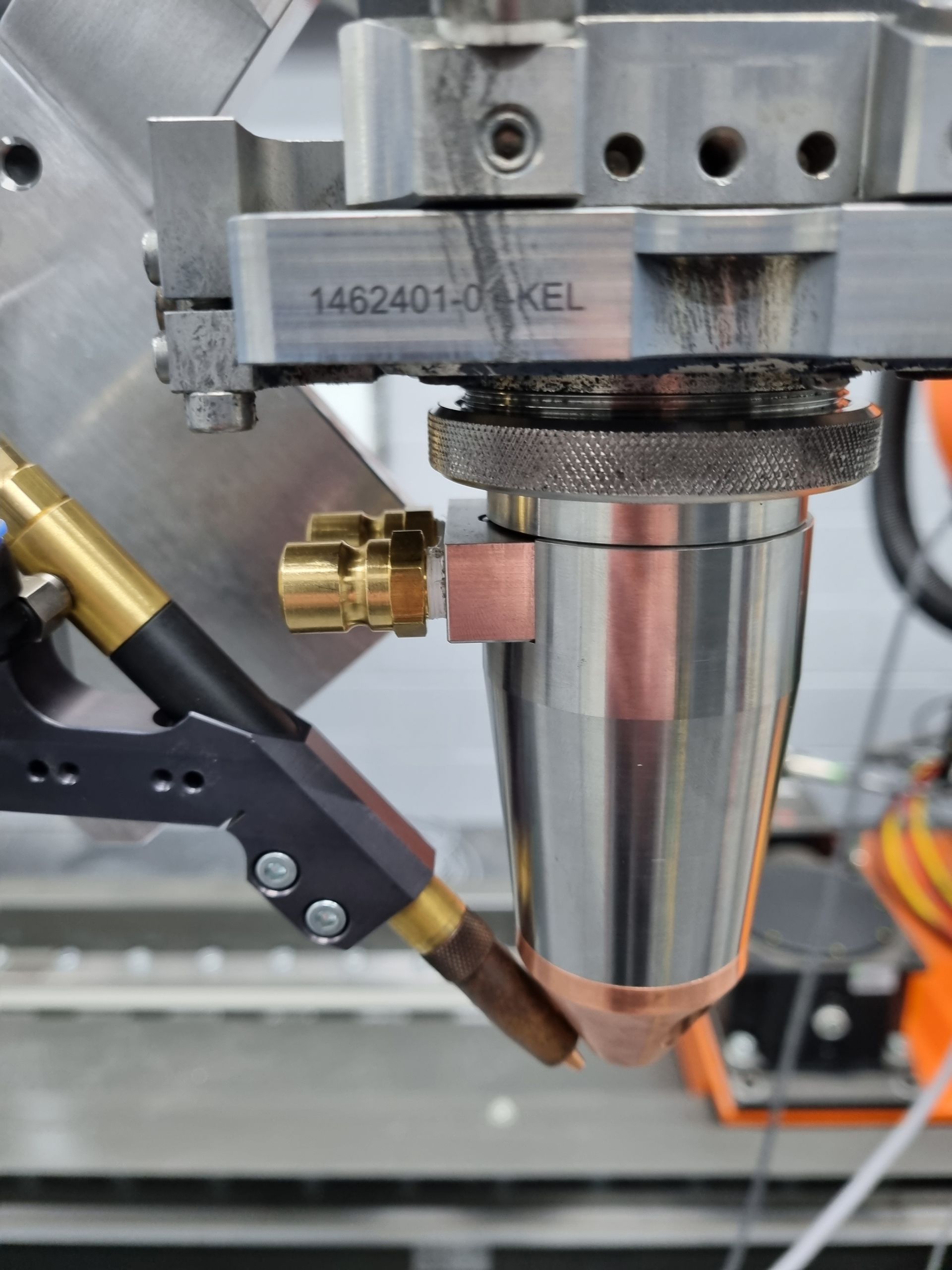

Our Innovate UK project named Wi-LAM (Wire and Laser Additive Manufacturing) focused on developing off-axis Wire DED for Inconel 718. This means the wire is feed in from an angle, as opposed to being feed through the center of the processing nozzle (co-axial).

The LAS team used a State-of-the-art Laser processing cell with integrated Wire feed capability, TRUMPF 3kW TruDisk Laser, 9-axis KUKA KR30 High Accuracy Robotic Manipulation System.

Our Conclusions

Wire Laser Direct Energy Deposition offers many advantages for manufacturing Inconel 718 parts, combining precision, material efficiency, and versatility to meet the demanding requirements of industries such as aerospace, Oil and Gas, Automotive and many others.