Laser Cladding ServicesLocated in Doncaster, UK

If you are looking for a company that offers Laser Cladding services, LAS has all the capability you need. Contact us with your queries.

Laser Cladding: for Applying Wear Protection

Laser Cladding, also known as Hard Facing or Weld Overlay, is where a material with a much higher wear resistance is welded onto the external surface of a typically expensive component. The cladded materials are often composite in nature, where ultra hard particles are supported in a more workable allow e.g. WC particles within a IN718 matrix.

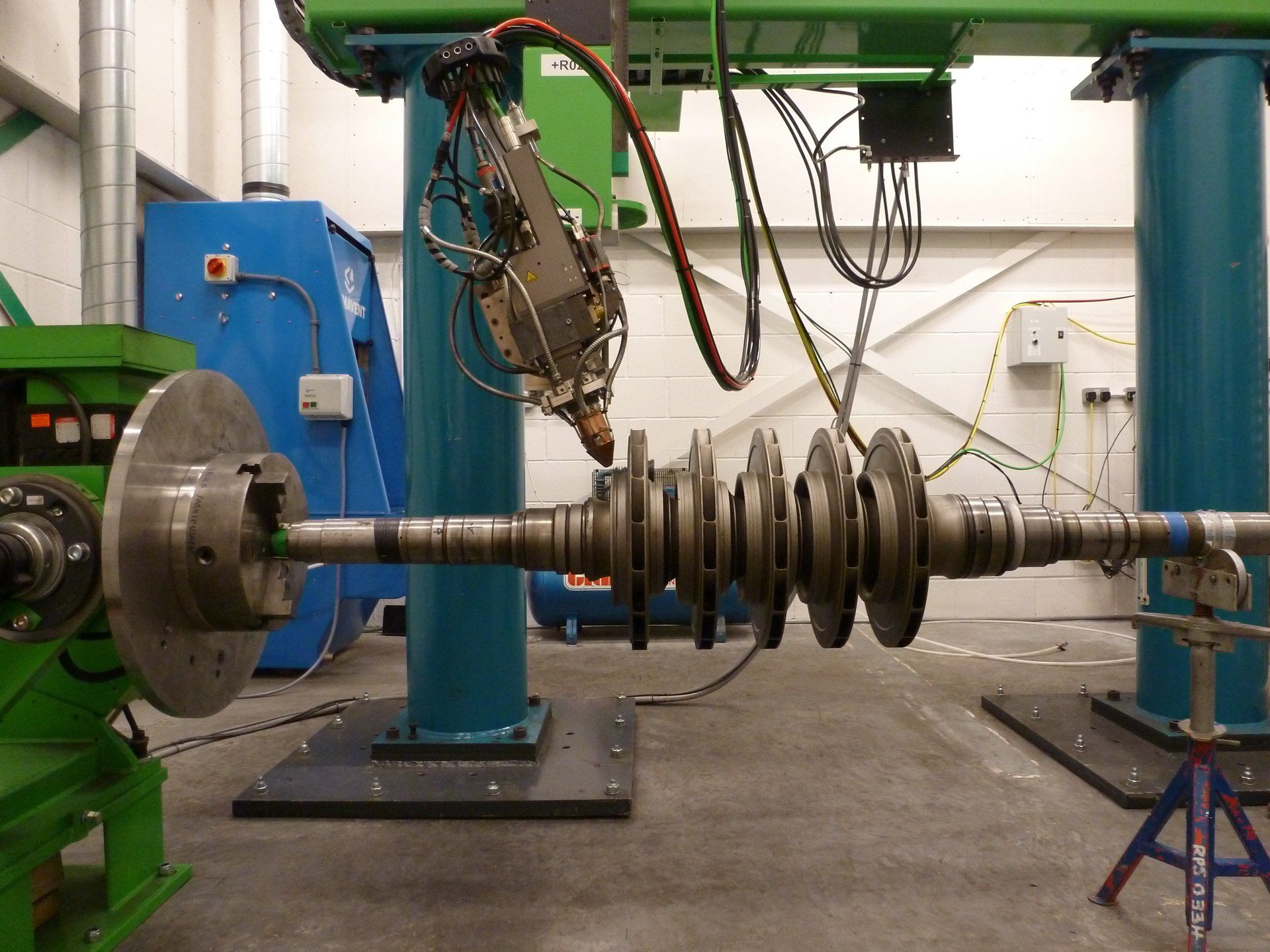

Laser Cladding can also be used to describe situations where simple 2-axis motion toolpaths can be used to clad either OD or ID surfaces. The combination of a constant part rotational speed and a linear axial movement can apply very consistent spiral welded coatings.

Laser Cladding:

Hard Facing

- Main objective is component working life-extension - usually driven by a desire for more wear resistance but could also be more corrosion resistance

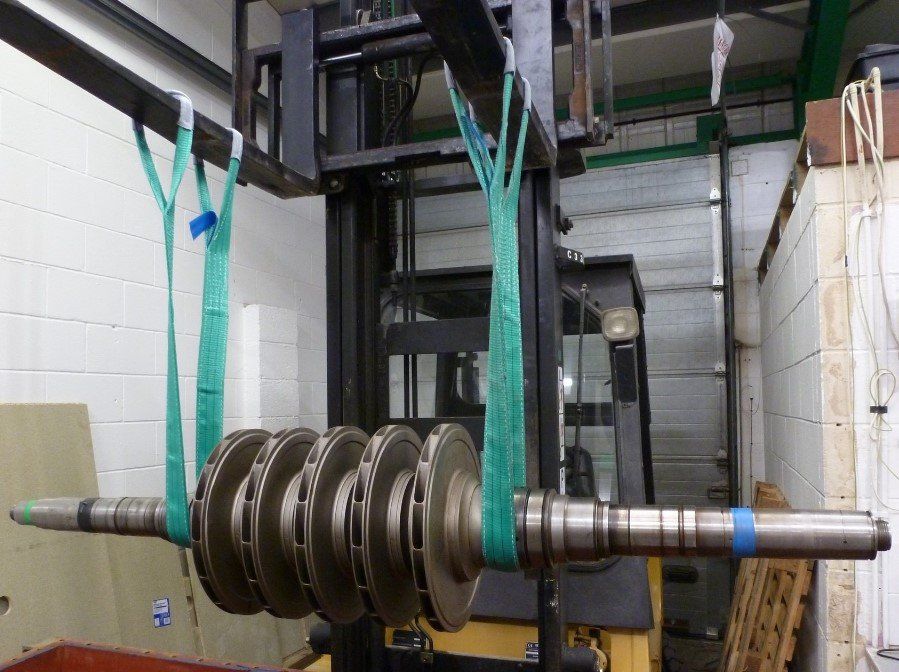

- Typically components being cladded are highly engineered and therefore expensive - such as downhole tools - but can also be the situation where accessibility for maintenance during service is limited or even zero.

- Cladded materials need to be chosen with reference to operating environment - is hardness, toughness, or abrasion resistance the key consideration?

- Laser Cladding is more about depositing large volumes of material rapidly - rather than keeping tight control of heat input and other variables in order to optimise deposit material properties (as with LMD).

Laser Cladding:

Outside Diameter Protection

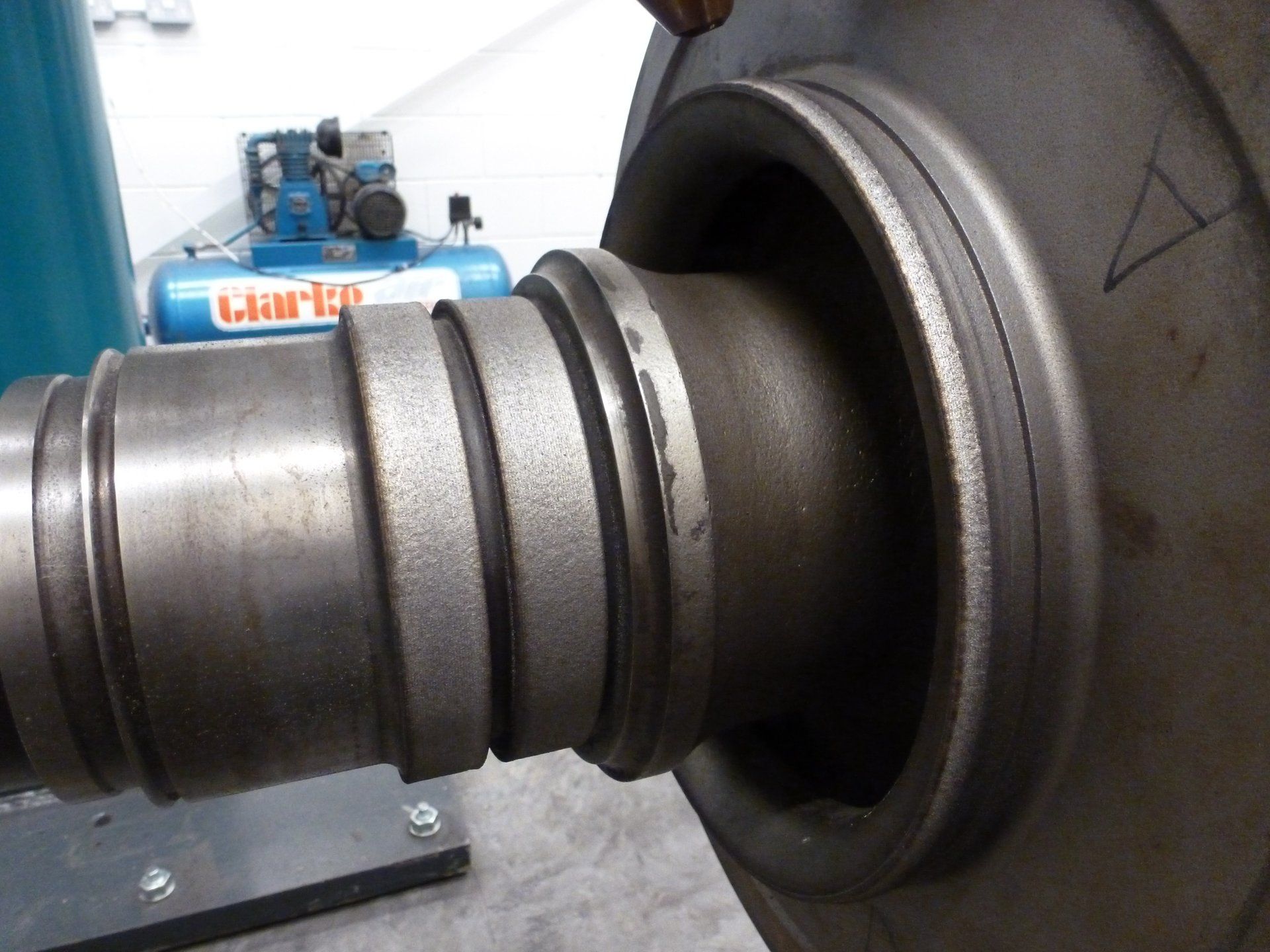

Laser Cladding is ideal for adding fully dense material to outside diameters. In the example below a matching high strength steel powder was used to build up the pre-machined diameters. Using a highly intense laser beam means the resulting weld pool is very small and the amount of dilution into the base material is controllable to within a few 0.1mm's.

For all your Laser Cladding requirements,

call Laser Additive Solutions Ltd on

01302 868 988