Metrology Services

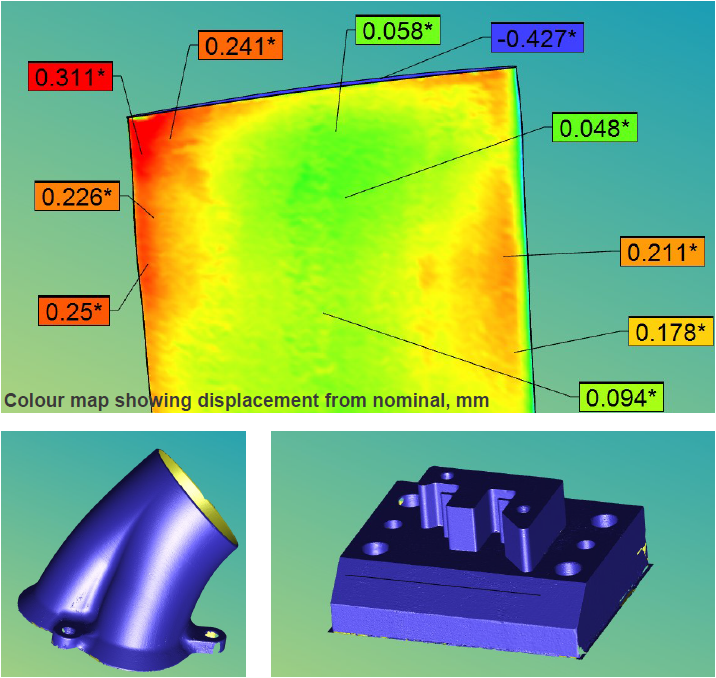

Laser Additive Solution can provide customers with a professional 3D Laser Scanning and measurement service.

Interested? Contact Laser Additive Solutions Ltd today.

3D Laser Scanning: for digitising real-world objects

3D Laser Scanning is a process by which a real-world object is scanned to produce a digital 3D CAD model. This digital model is useful where reverse engineering is required, or where complicated measurements must be made.

About

Laser Scanning equipment

LAS have invested in state-of-the-art 3D laser scanning equipment used in the reverse engineering of components. Our software is able to produce mesh CAD models in all major formats, and boasts speed and cost efficiency when compared to traditional tactile probing.

Benefits

Portable

The ROMER Portable Scanning Arm, is a portable CMM Laser Scanner manufactured by the renowned Hexagon Manufacturing Intelligence. The portable nature of the equipment means that components can be shipped to LAS for scanning, or LAS can scan components on-premises preventing the potential damage of delicate components as a result of shipping.

Precise

Our equipment is highly accurate, and scans components with a precision of 63 microns or better (based on a component size of 2.5 metres). Lower precision is possible if your requirements allow, resulting in the output smaller CAD files.

Instant Access

All CAD files we produce can be made available instantly and securely via the cloud, at no extra cost. This means we don't have to outsource this service, reducing the hassle and cost for our customers.

Inspection equipment

LAS have invested in state-of-the-art hard probe inspection equipment and software that can be used in-house at LAS or at your premises from Hexagon Metrology. If you have valuable or difficult to move parts, or it just makes much more sense for us to visit you, we have highly capable engineers available on a 7-day a week basis.

Measurement Service

LAS provide a measurement service for scanned components. A measurement accuracy of 38 microns or better is possible (based on a component size of 2.5 metres), and the process can provide measurement data for otherwise difficult geometries.