RE-LACS – DASA Funded Development Project

Introduction

The RE-LACS project demonstrated how an automated reverse engineering and laser metal deposition (LMD) repair system could be integrated with a 6-axis robot and housed within a 20ft shipping container, making it suitable for the rapid repair of a wide range of metal components within the military logistics arena.

Parts to be repaired

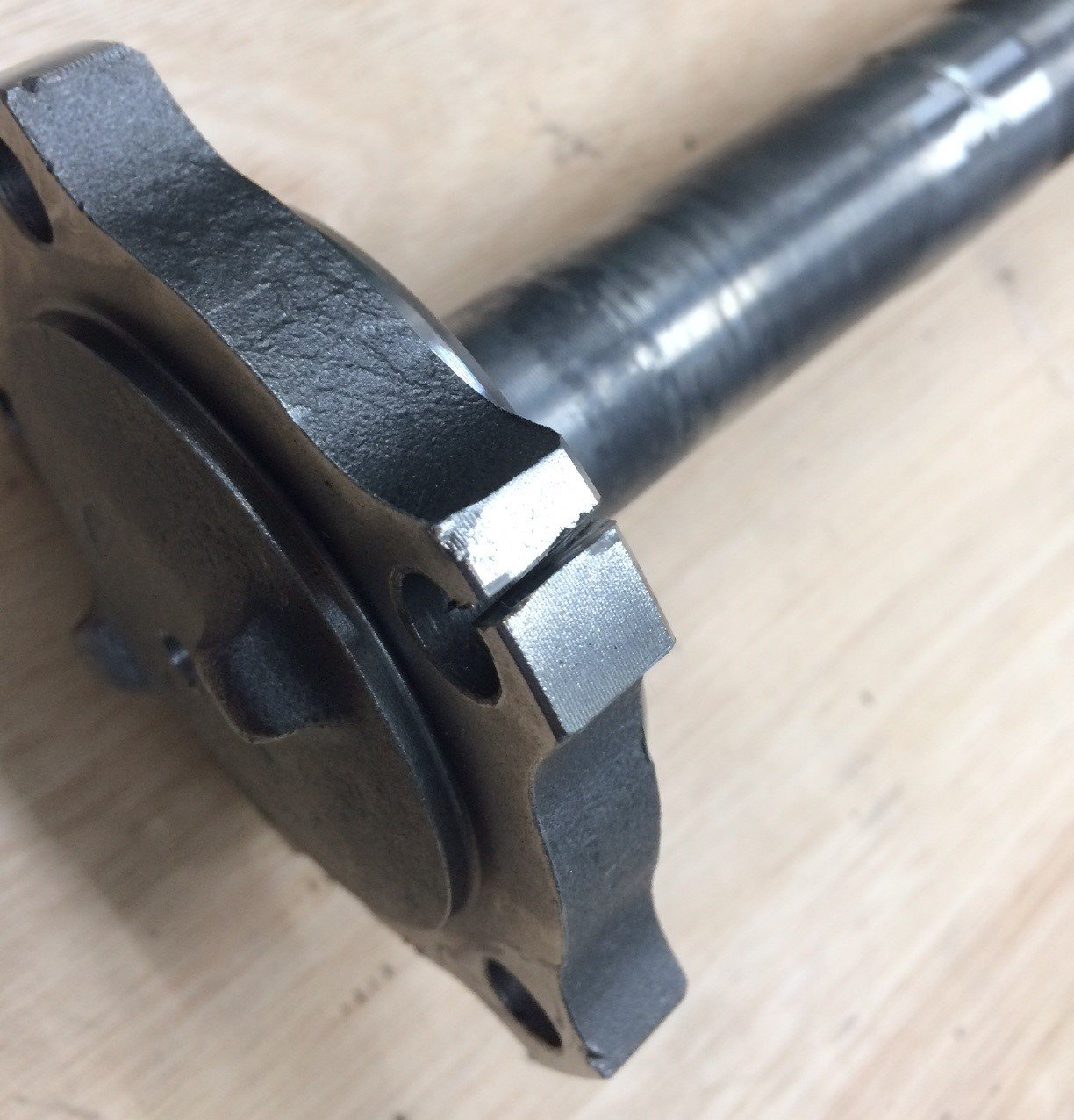

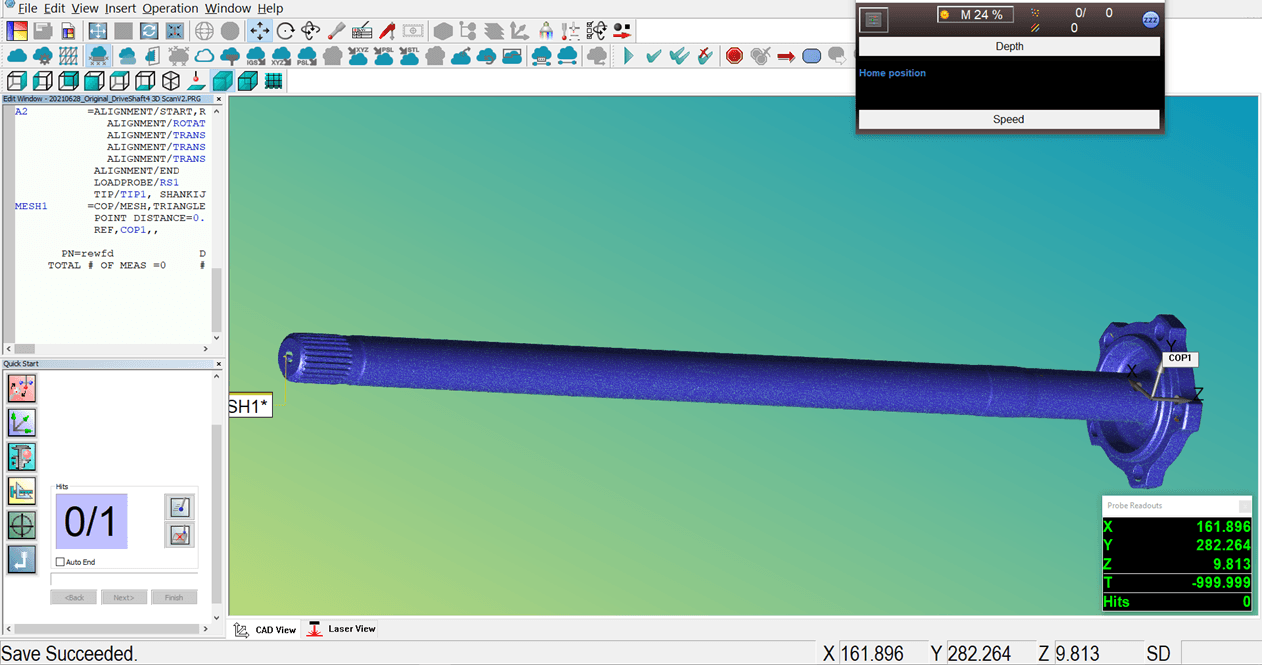

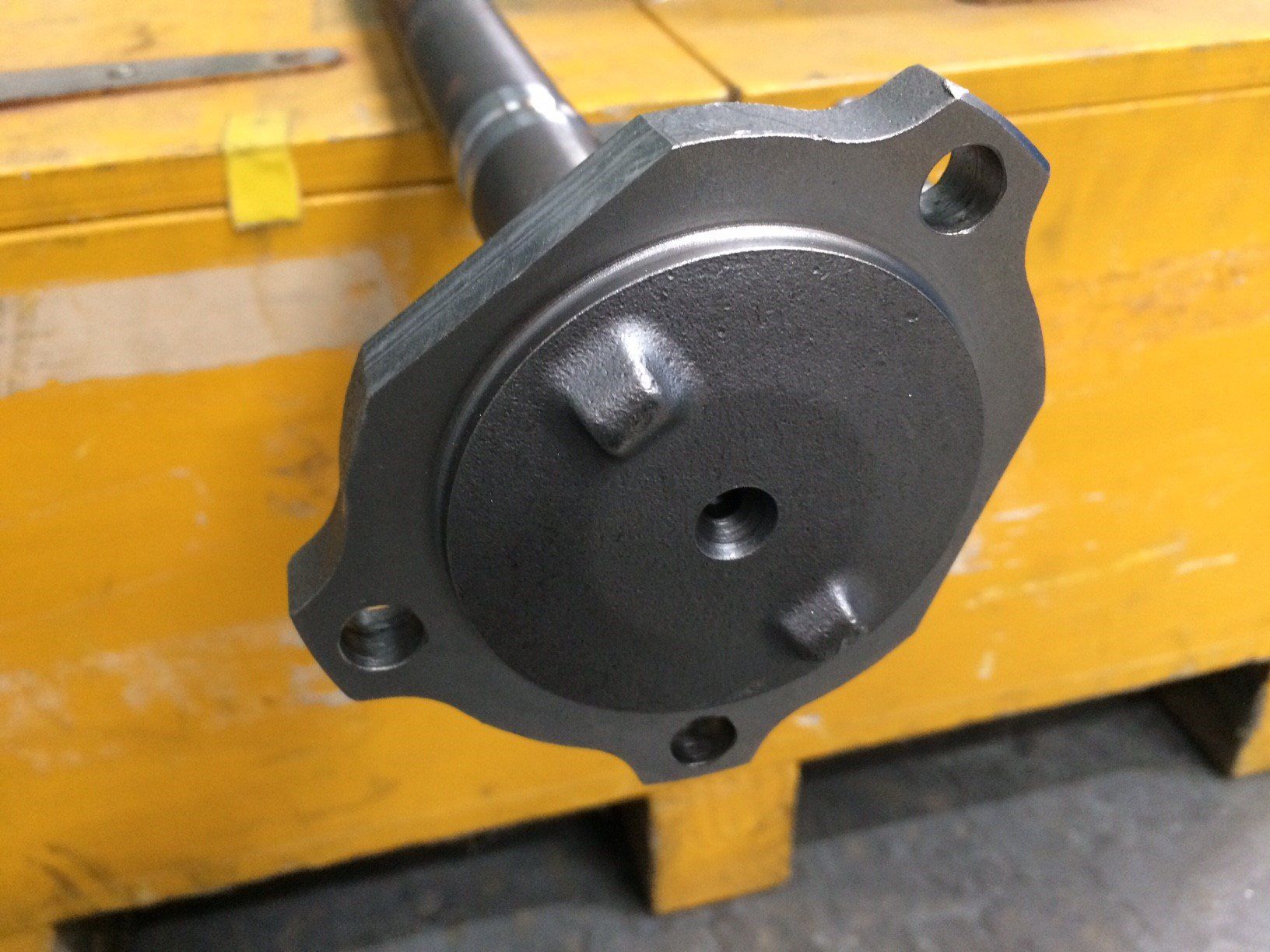

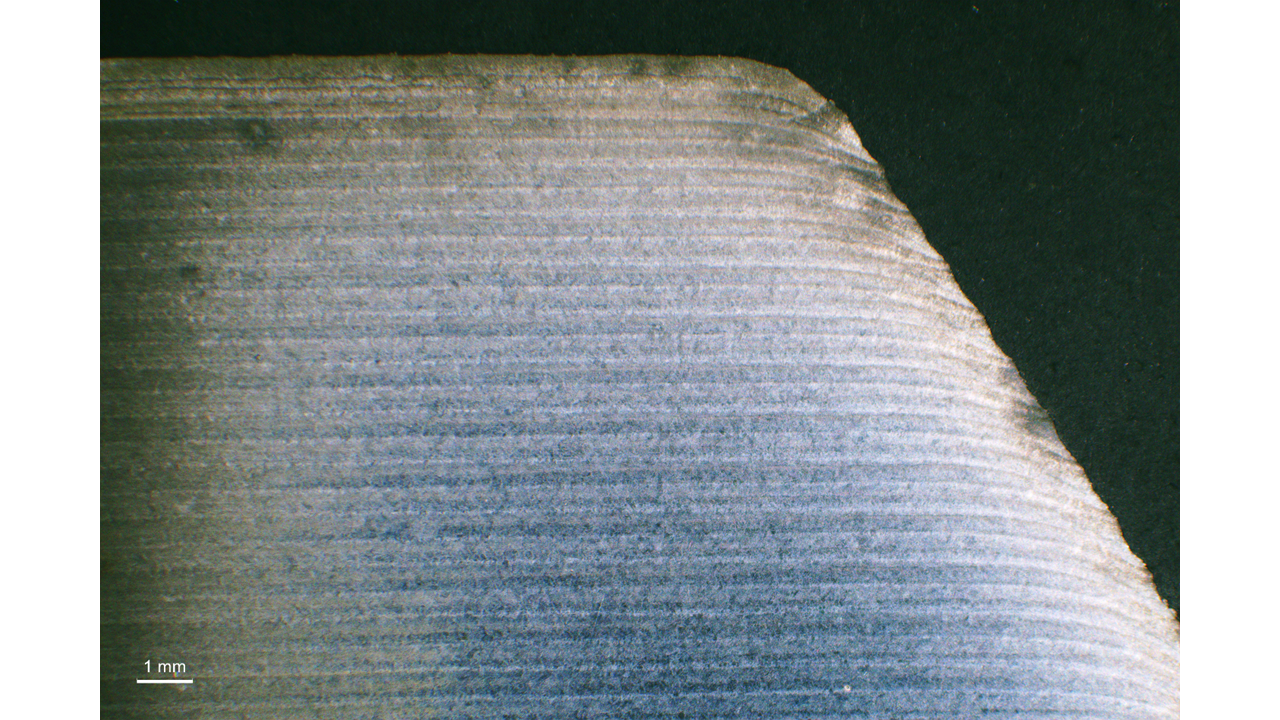

Land Rover Defender drive shafts were chosen as suitable parts to demonstrate the concept. Parts were procured and 3D scanned at Laser Additive Solutions’ site, using their in-house laser scanning equipment. This captured the 3D geometrical data for the parts which was then used for generating a 3D CAD model of the part.

RE-LACS Container Fit-out

A 20ft shipping container was procured by LAS, refurbished and fitted out with a control room, external roller shutter doors, lighting, electrics and interlocking safety features.

A second-hand Reis RV16 industrial robot was also procured and installed in the shipping container, which would control the laser required for the LMD repair operation.

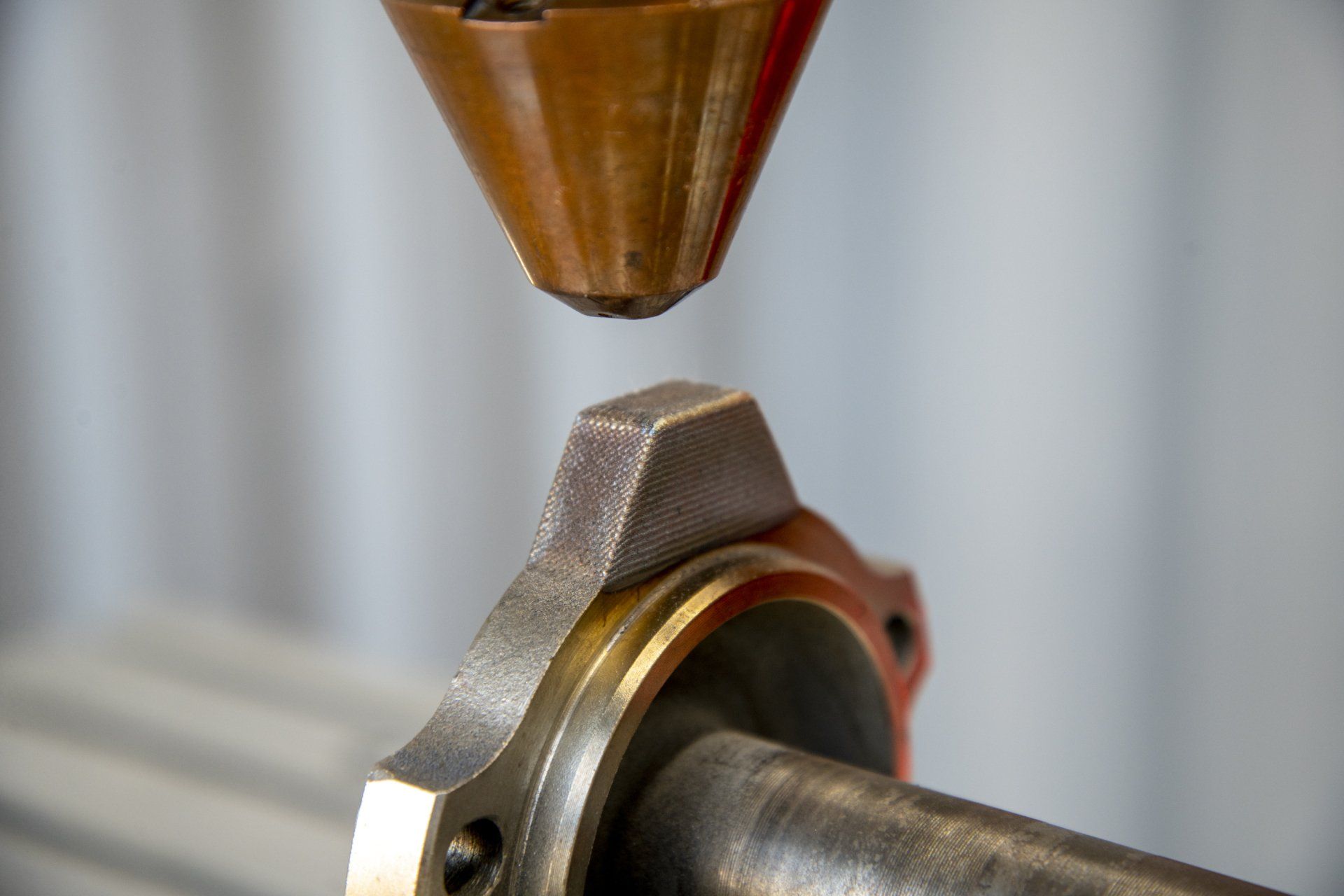

Additionally a machining head was procured and fitted to the robot in order to demonstrate how the machining operation could be integrated into the RE-LACS cell.

Cameras and monitors were installed in the cell’s control room in order to control and monitor the process, and an externally mounted monitor was also installed.

Final System Demonstration

A series of demonstrations of the RE-LACS cell’s capability were given at the LTI Showcase Demonstration event at MoD Lyneham between 27th September 2021 – 7th October 2021. Full 3D laser scanning capability was available and demonstrated but due to restrictions associated with the use of lasers on the MoD site, the LMD repair operation could not be carried out on site. The RE-LACS cell robot therefore demonstrated a simulation of the repair operation, whilst videos were shown of the actual LMD repair operation in LAS’s factory environment. The RE-LACS project as demonstrated that a high integrity and rapid laser based metal repair system can be housed within a mobile container, suitable for deployment within harsh and remote environments.