Bespoke Repair Serviceslocated in Doncaster, UK

If you are looking for a company that offers the highest quality repair services, you have come

to the right place. Please see below on how we can help.

Bespoke Repair: for Recovery of Components

Bespoke repair is the process of adding small amounts of material to high value items so that

they can be put into service again.

At LAS we use an automated machine tool and a laser beam to repair damaged parts - in some cases we also need to use our 3D Laser Scanning equipment to confirm the geometries we are repairing.

Bespoke Repair:

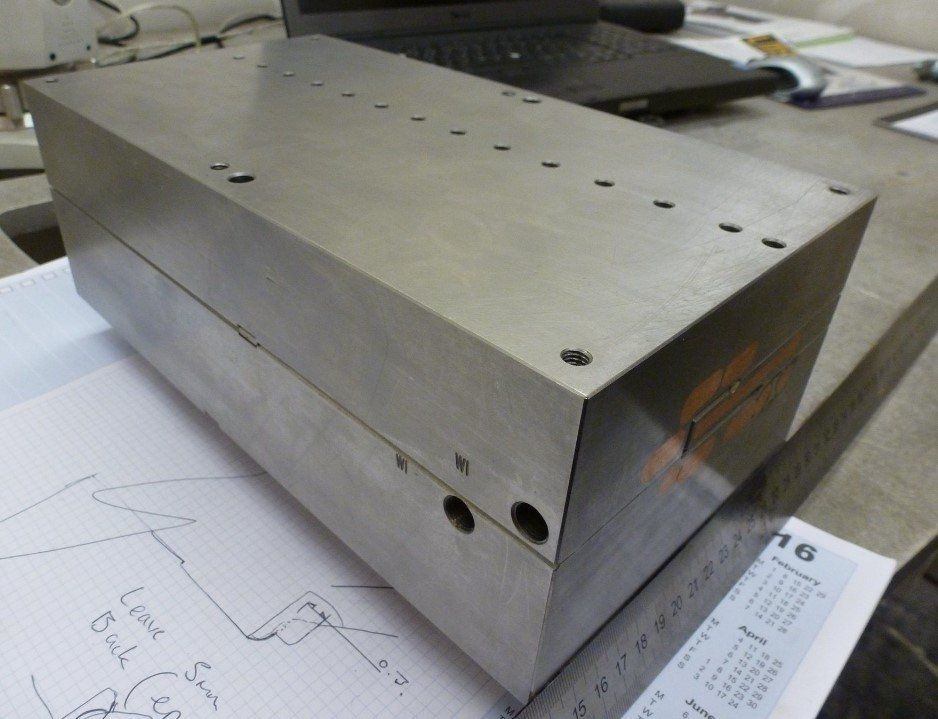

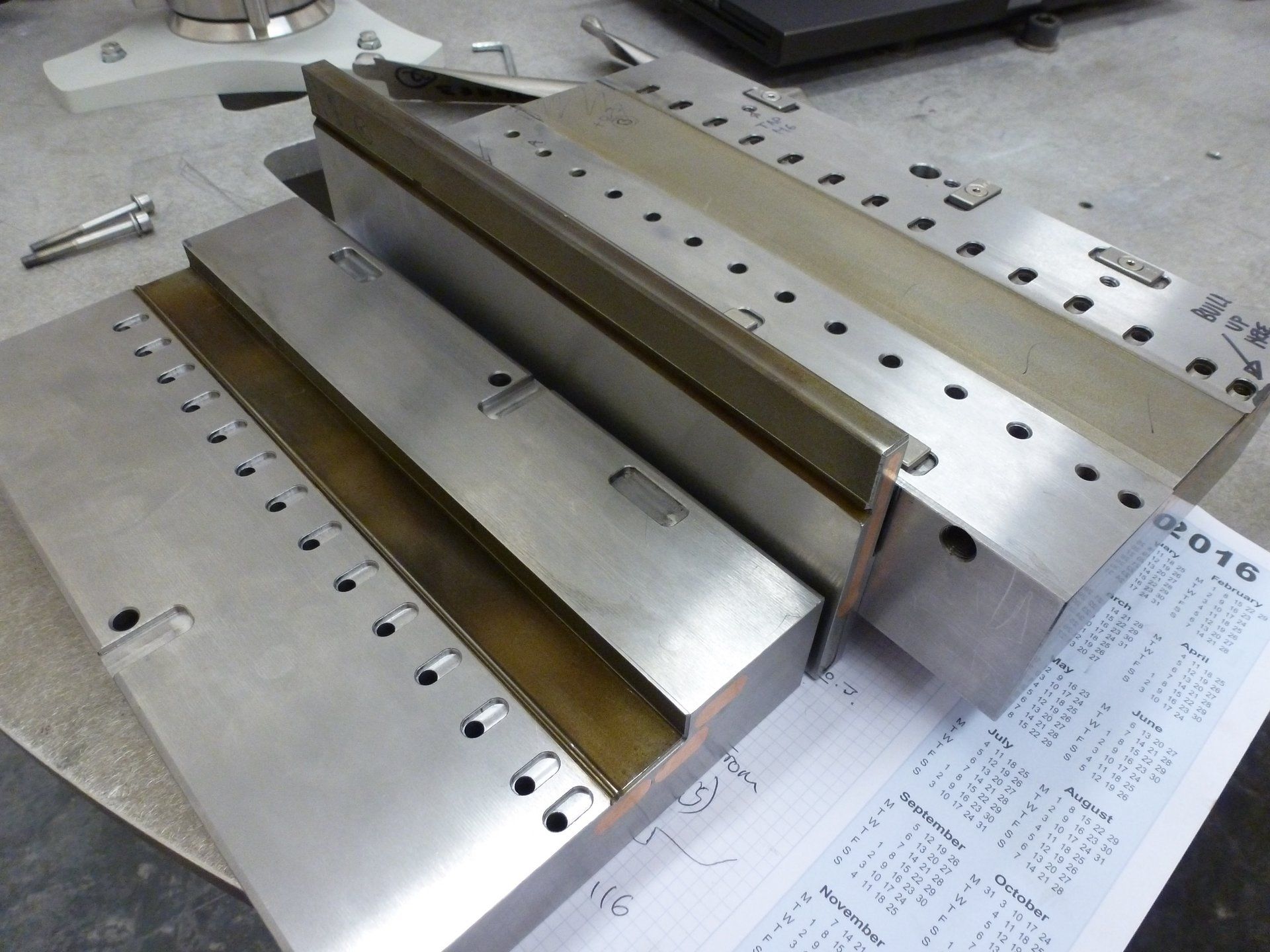

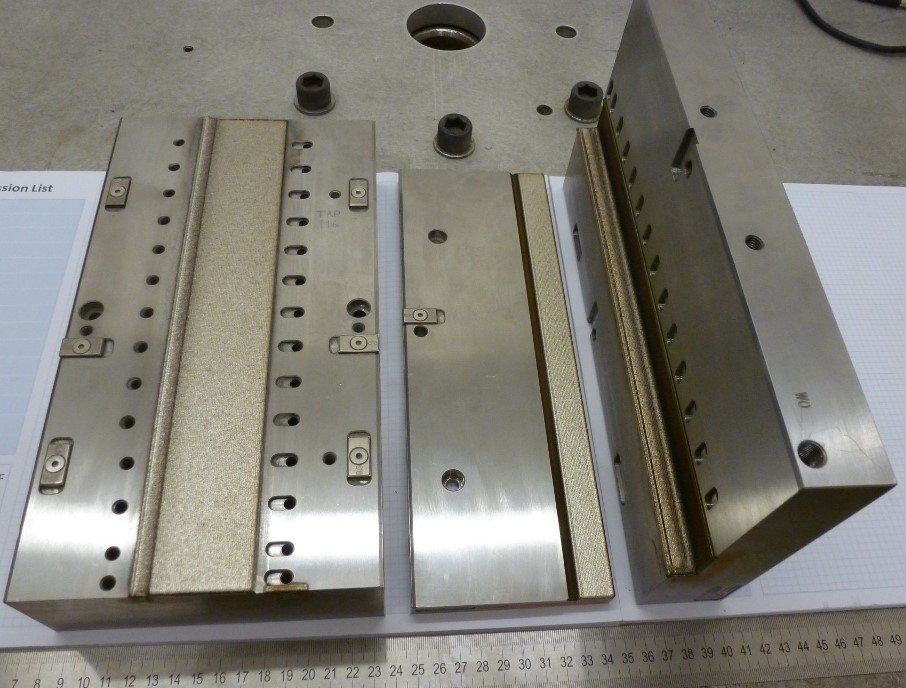

Plastic Extrusion Tools

- LAS work closely with a number of tooling companies

- Parts are usually hand delivered to LAS by the customer and depending on the situation e.g. production line stoppage, repairs can be completed on a 'as you wait' or 24/48 hour basis

- LAS competitors usually use mobile manual laser weld systems to perform these repairs

- Manual systems are cheaper on a hourly basis but with the automated Weld Repair system at LAS tools can be repaired significantly quicker and therefore more cheaply

- Heat input is absolutely minimal - parts can be generally picked-up by bare hands directly after welding

- Resulting weld surfaces are very smooth and are therefore simple to grind to final dimensions post-welding

Bespoke Repair:

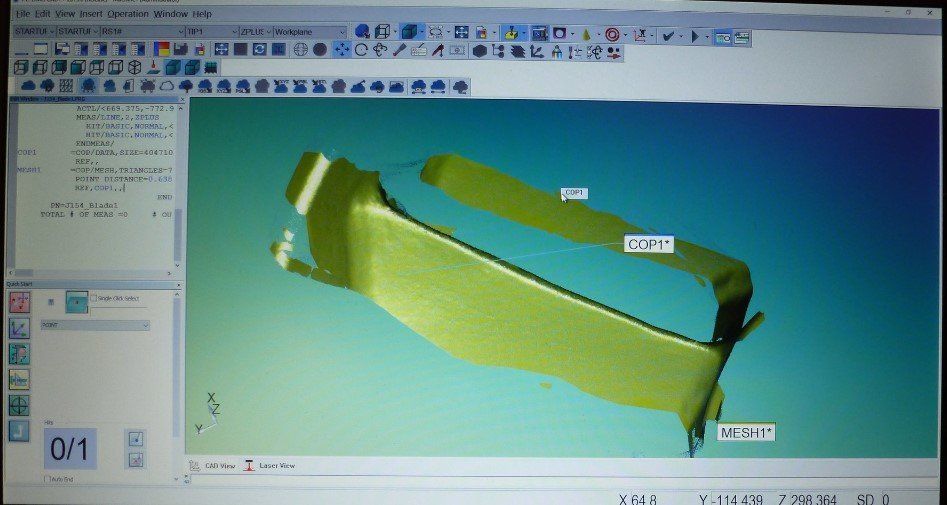

Complex Components

LAS have invested in a very advanced Laser Scanning system so that even the most complex geometry can be perfectly repaired (some accessibility limitations apply). Many components delivered to LAS are of unknown geometry e.g. accurate CAD models of not exist, and so LAS regularly Laser Scan components (also known as Reverse Engineer) in order to create bespoke CAD models of each component. This allows the creation of weld toolpaths that match exactly the delivered geometries.

For Bespoke Repair Services, call Laser Additive Solutions Ltd on

01302 868 988

Or email us at enquiries@laseradditivesolutions.co.uk